for Automotive and Appliances Industry for nearly 02 decades.

Six Sigma and aiming for 0 PPM

TRIANGLE

Get your sheet metal parts manufactured with precision and quality.

Manufacturer for Automotive Industry for nearly 02 decades.

Flexible Shopfloor Capacity, Capability and Scalability.

Who We are?

Welcome to MicroTech Pressings – your trusted partner in precision sheet metal manufacturing since 2007. As a leading manufacturer specializing in sheet metal parts and components, we take pride in serving the automotive, white goods, home appliances and engineering sectors with excellence. Our expertise in precision sheet metal stamping, progressive tool components, and welded sheet metal sub-assemblies is backed by our ISO 9001:2015 certification, ensuring that we meet your needs with the highest quality, on time and within budget – tailored to your exact specifications.

Our Core Services

Over 17 years of experience & knowledge, in sheet metal press tool components, dedicated to provide the best economical solutions to our valued customers.

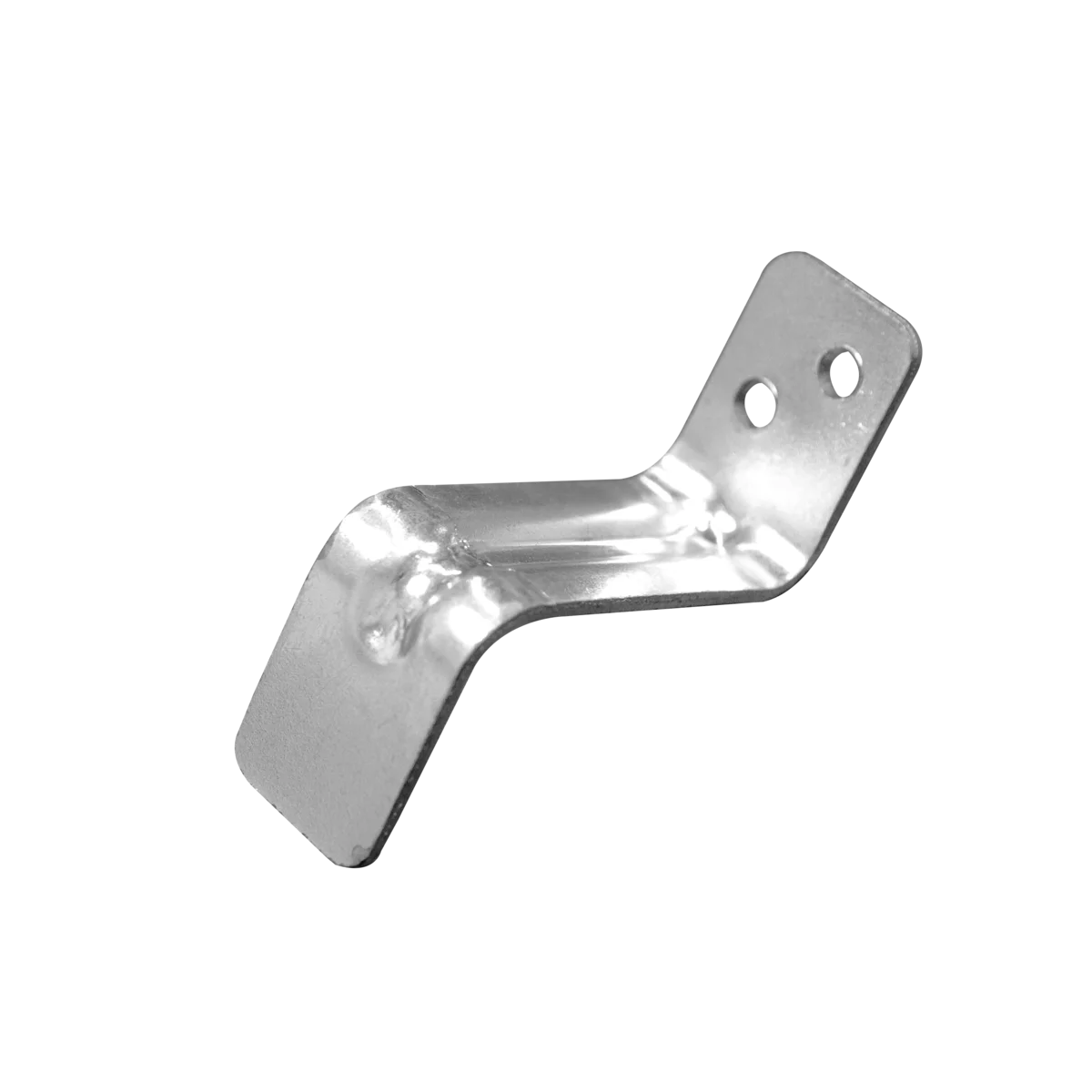

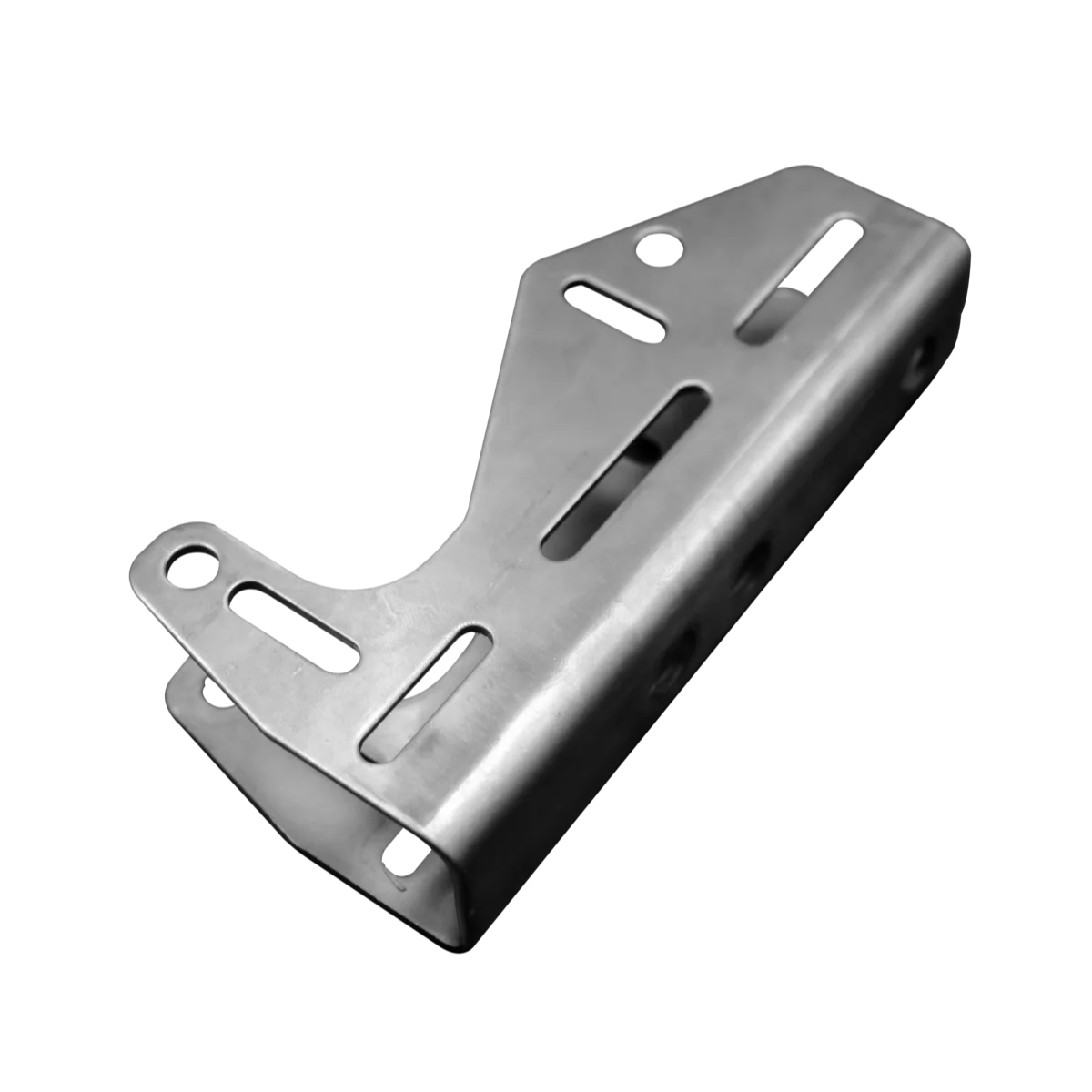

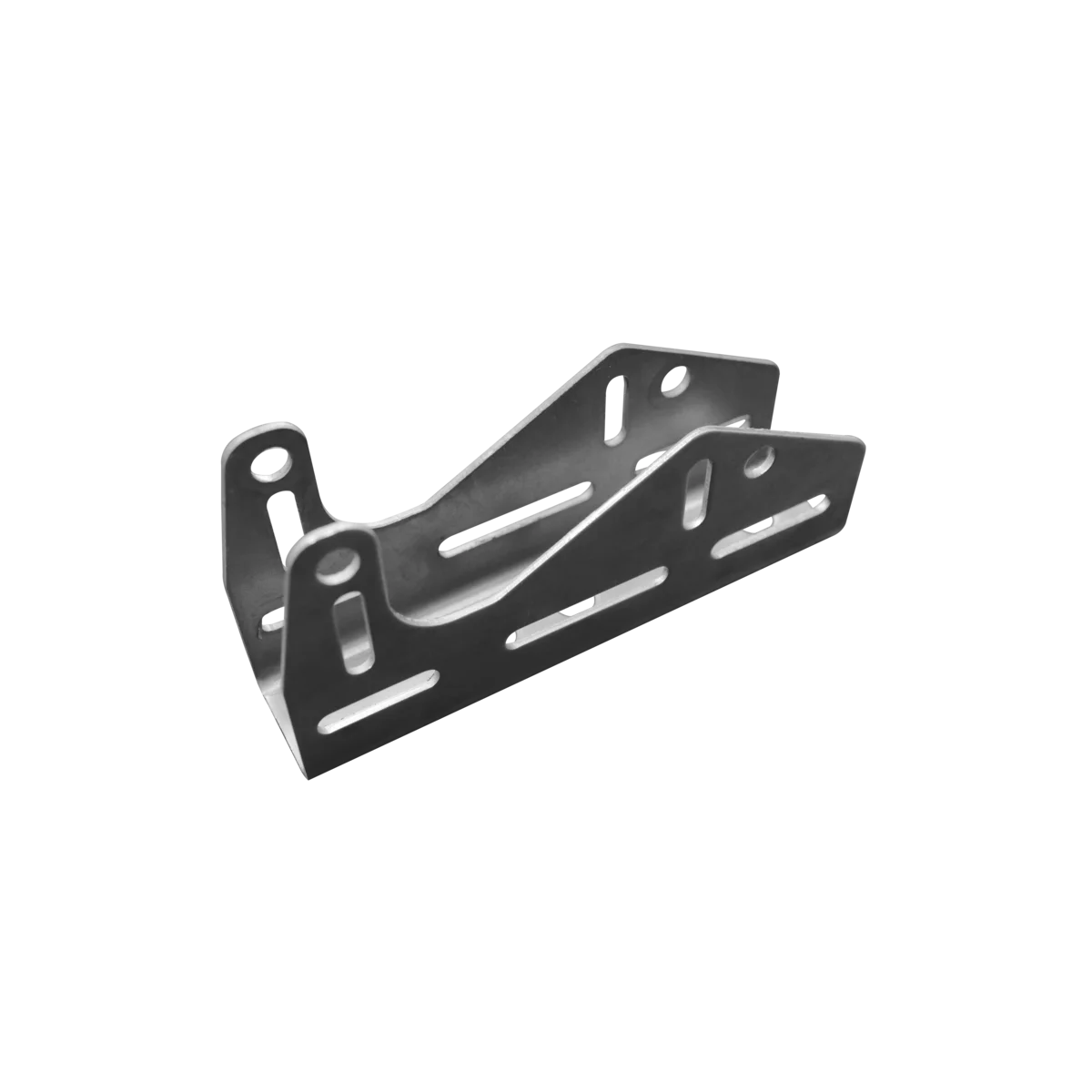

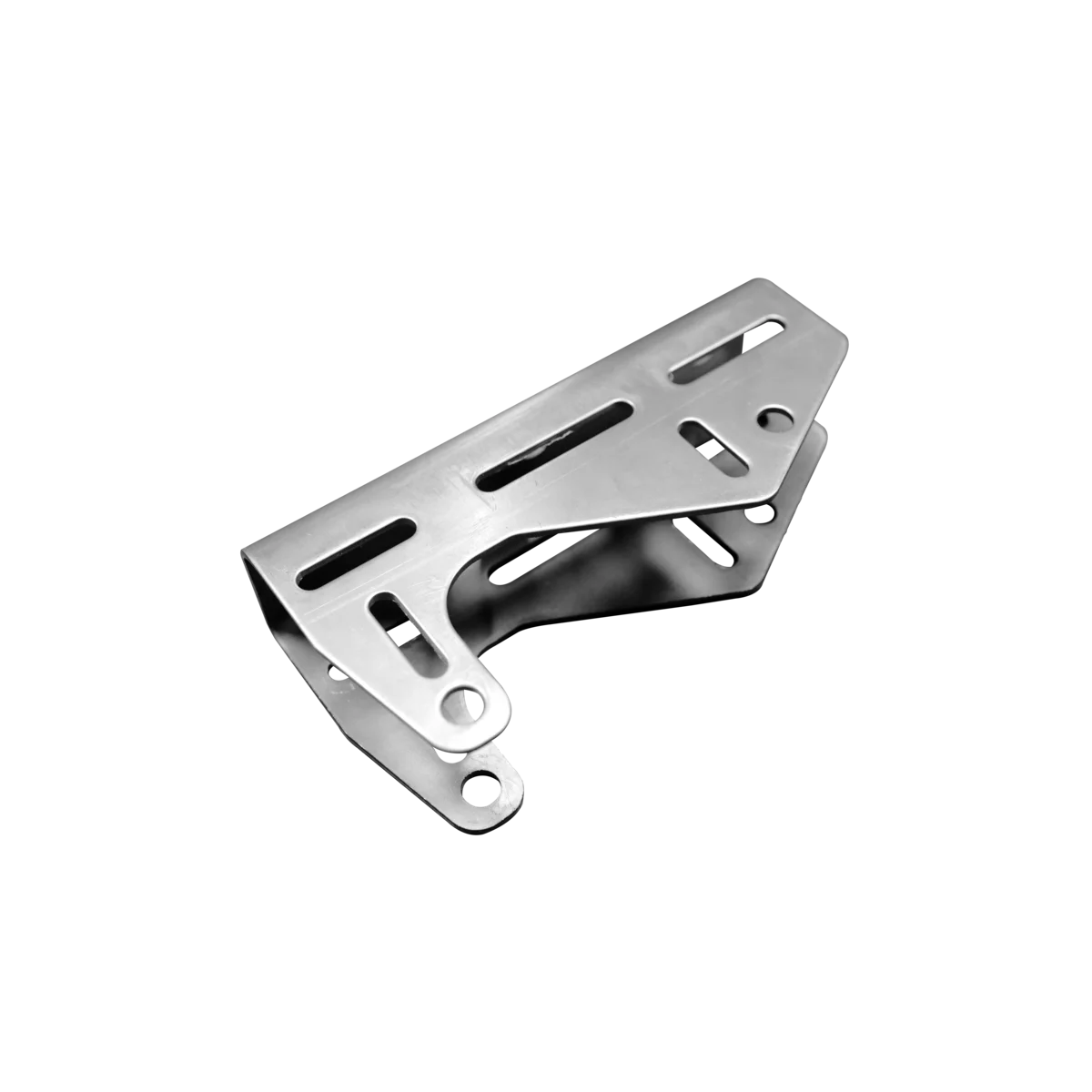

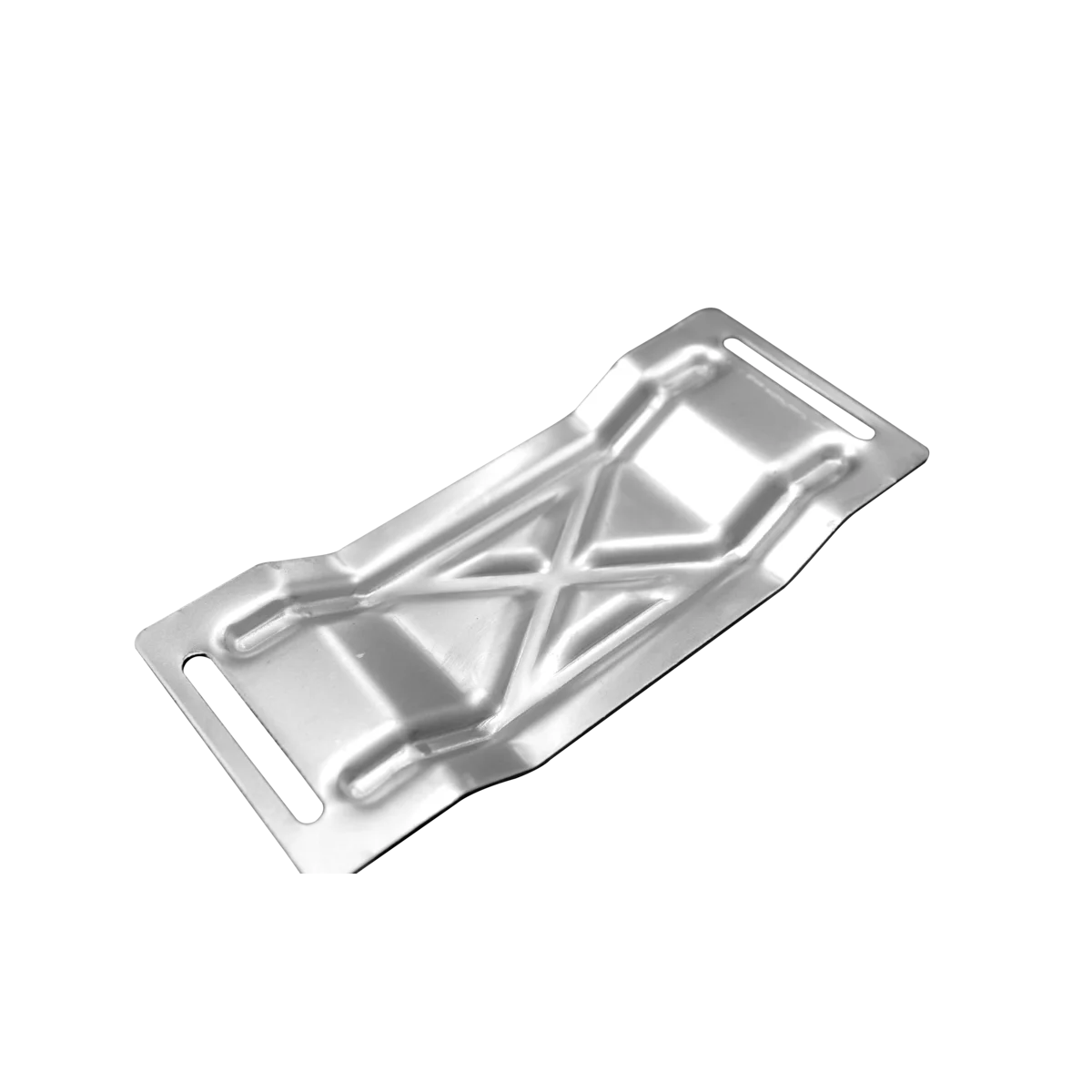

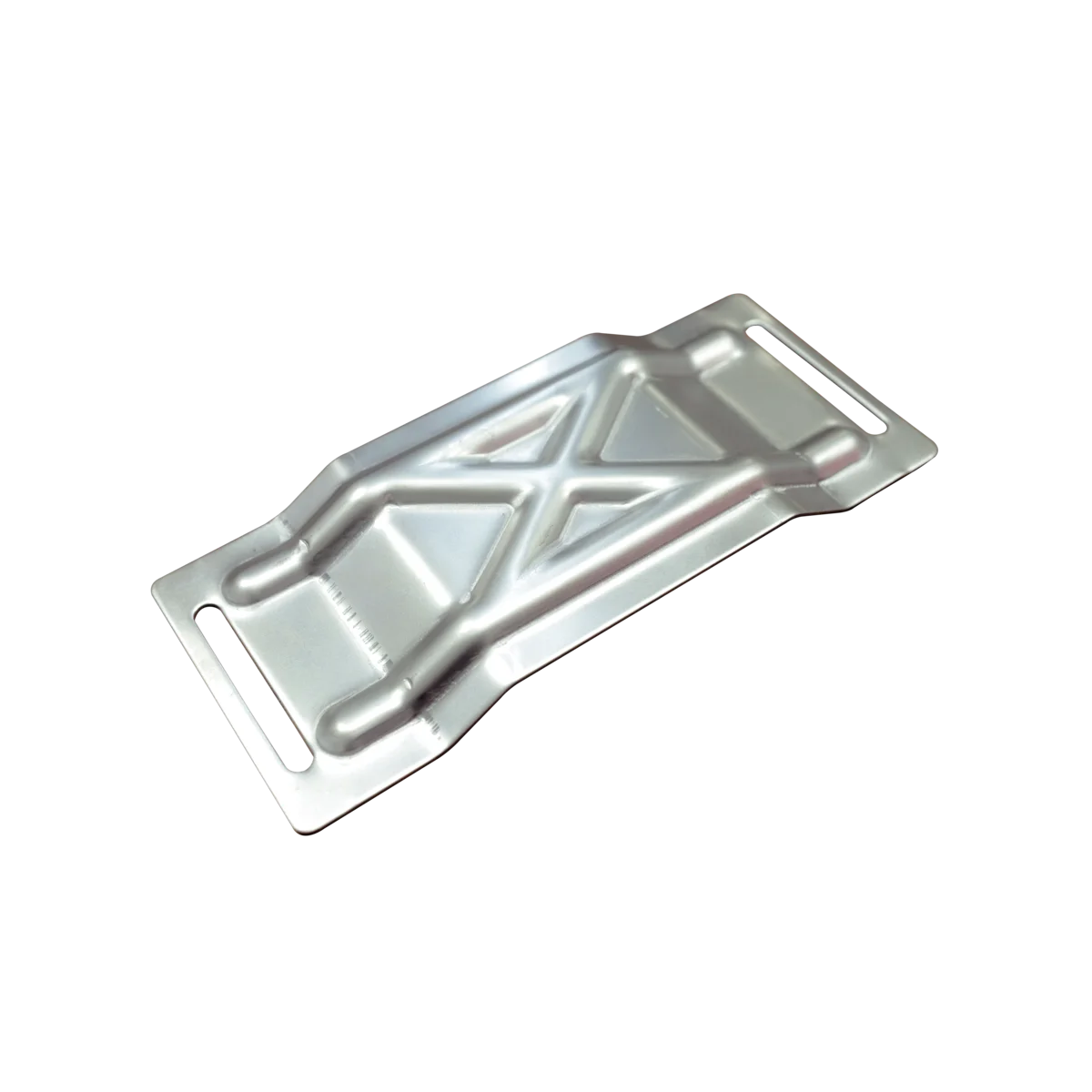

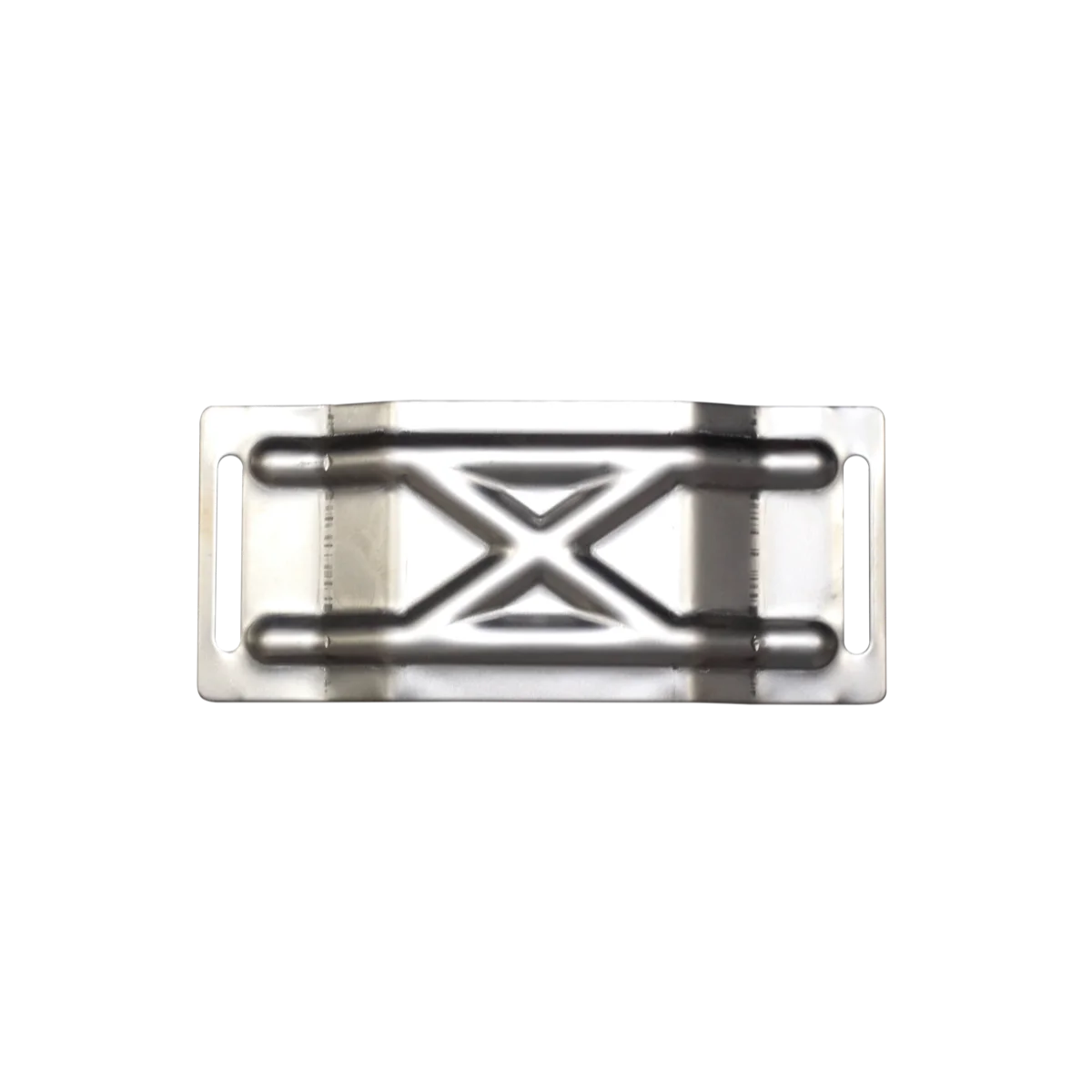

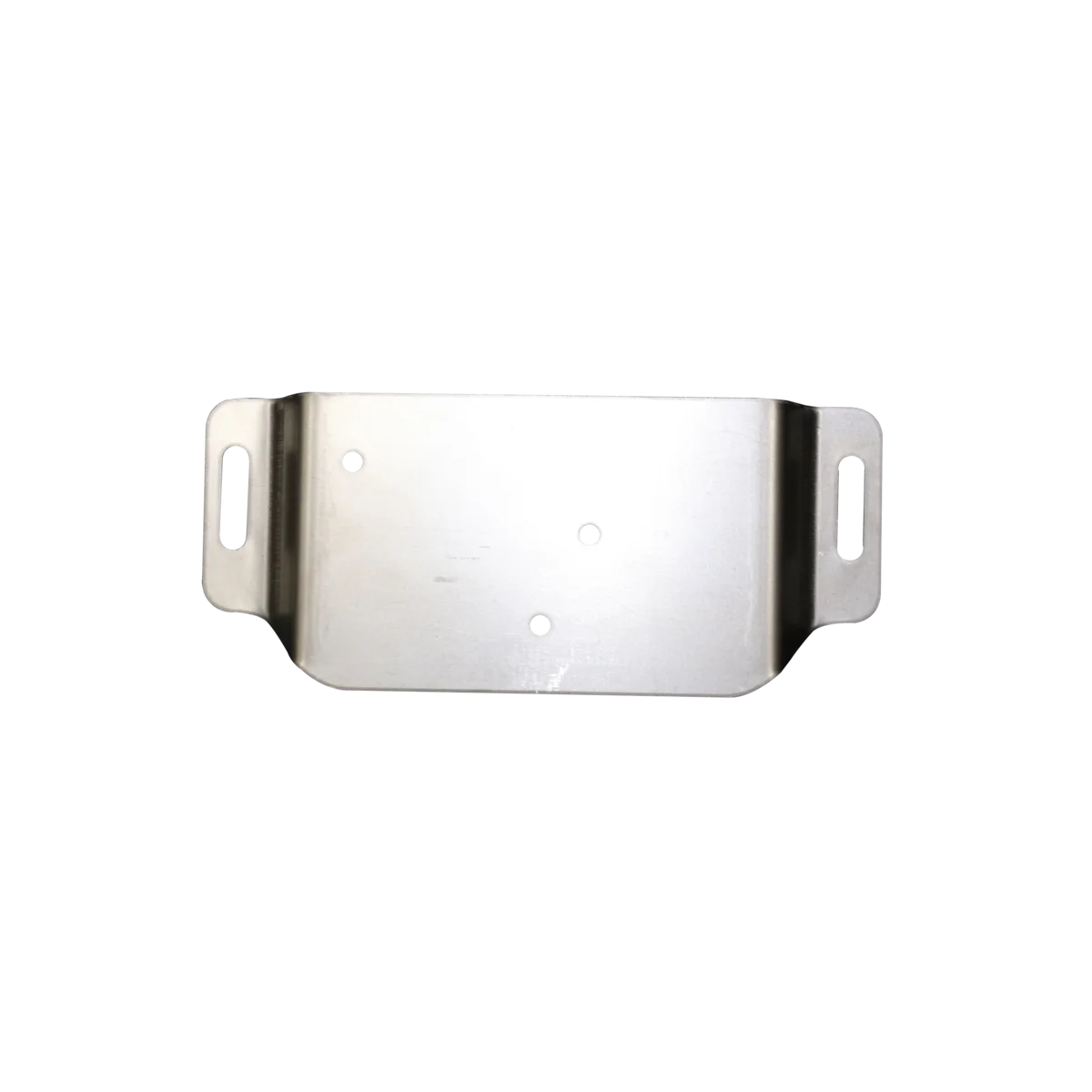

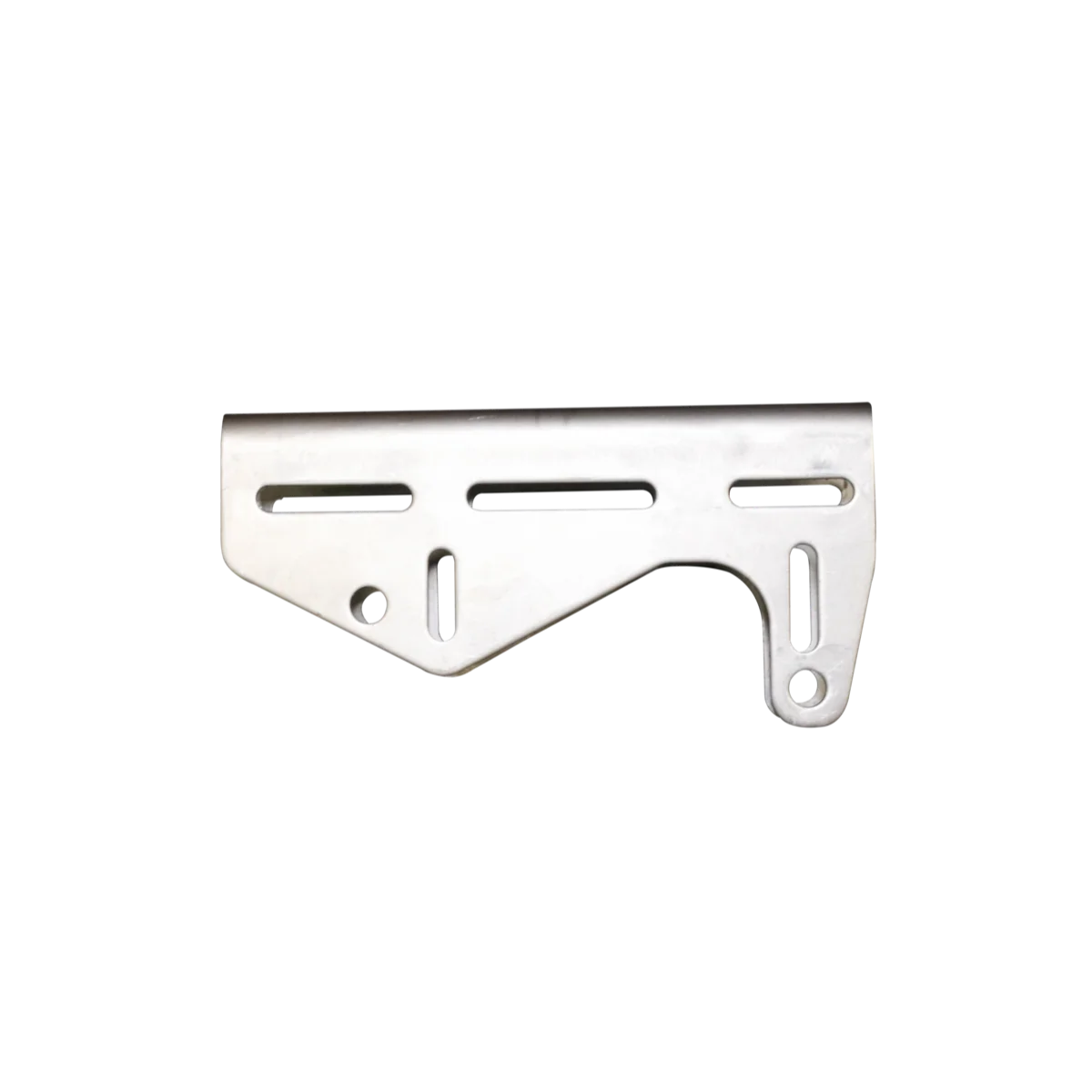

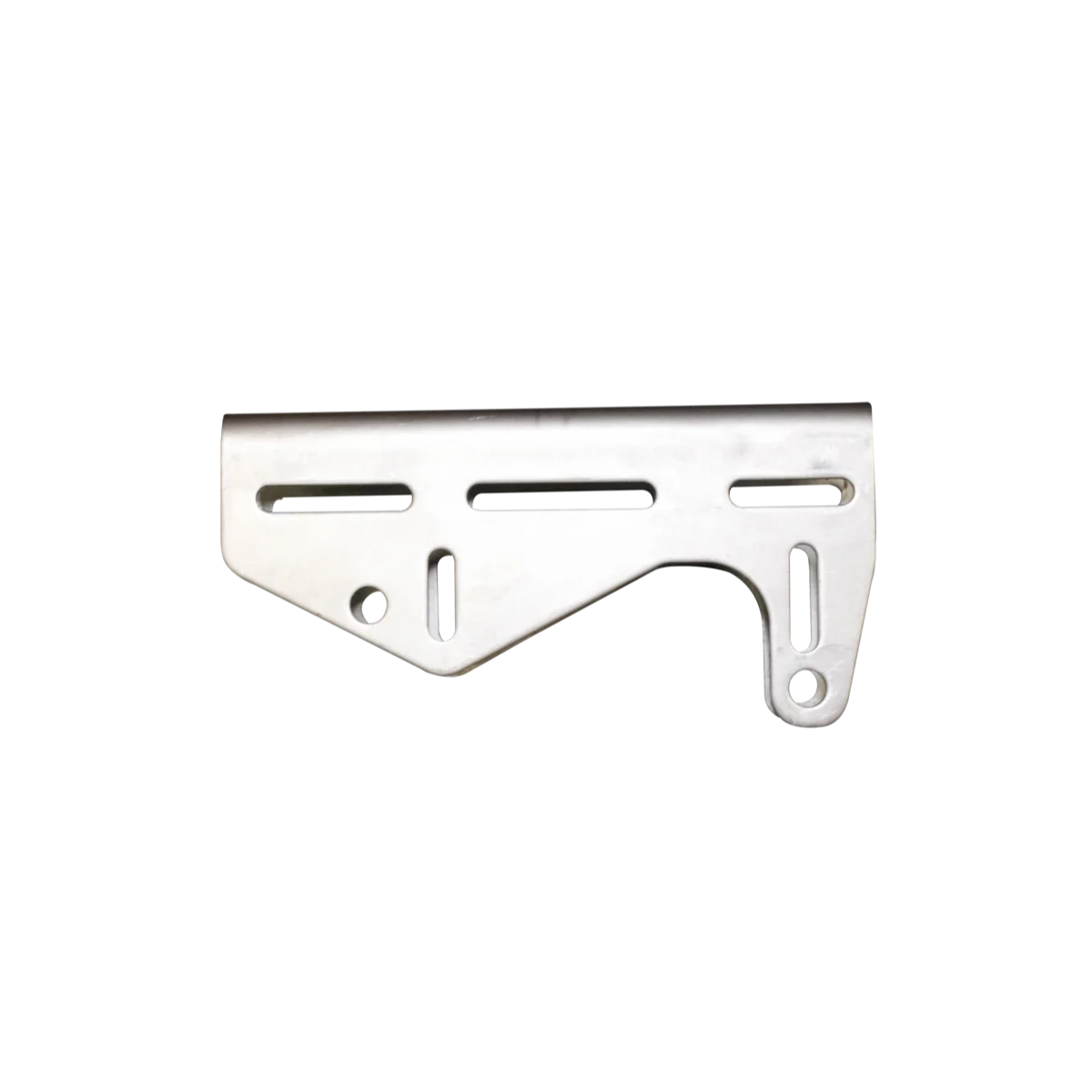

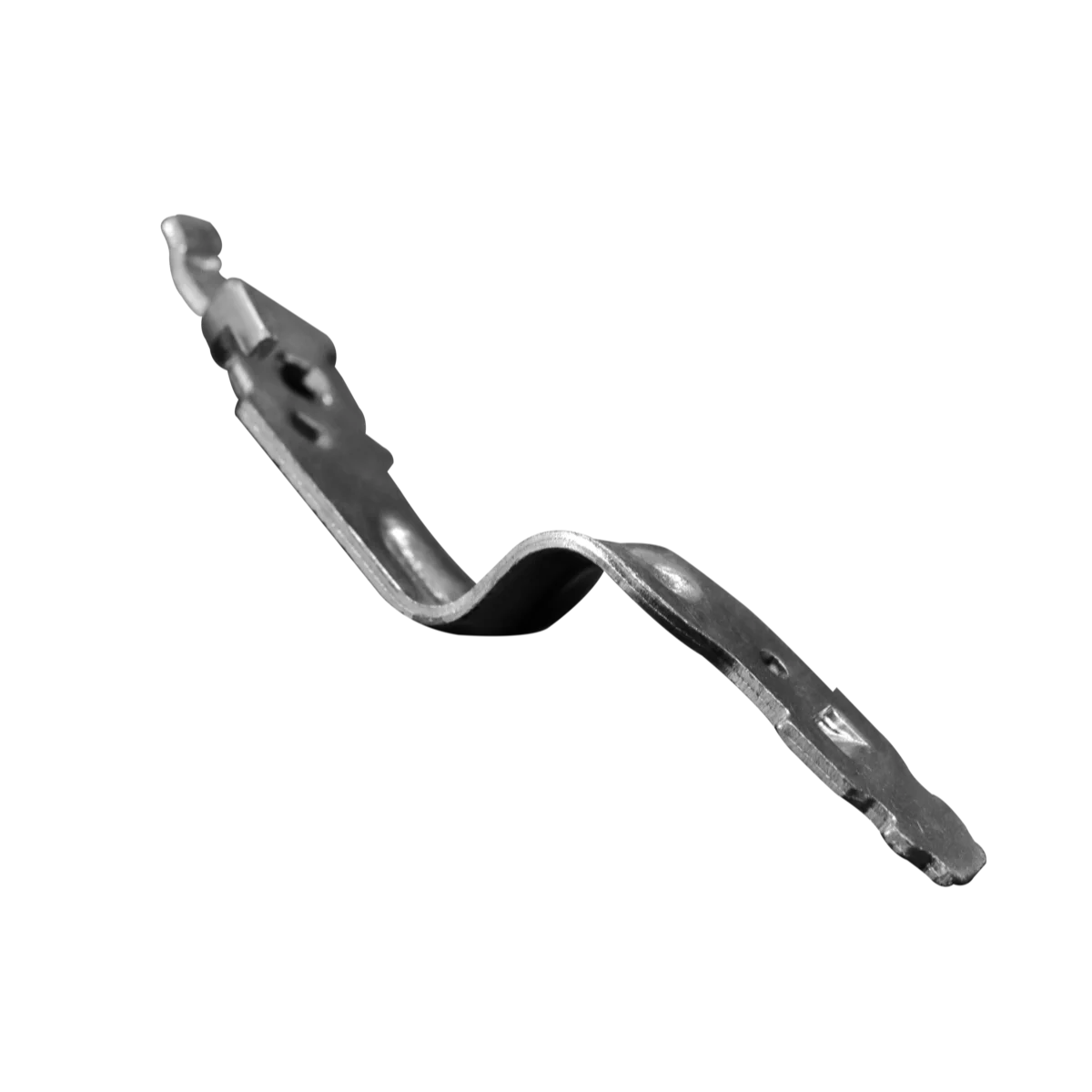

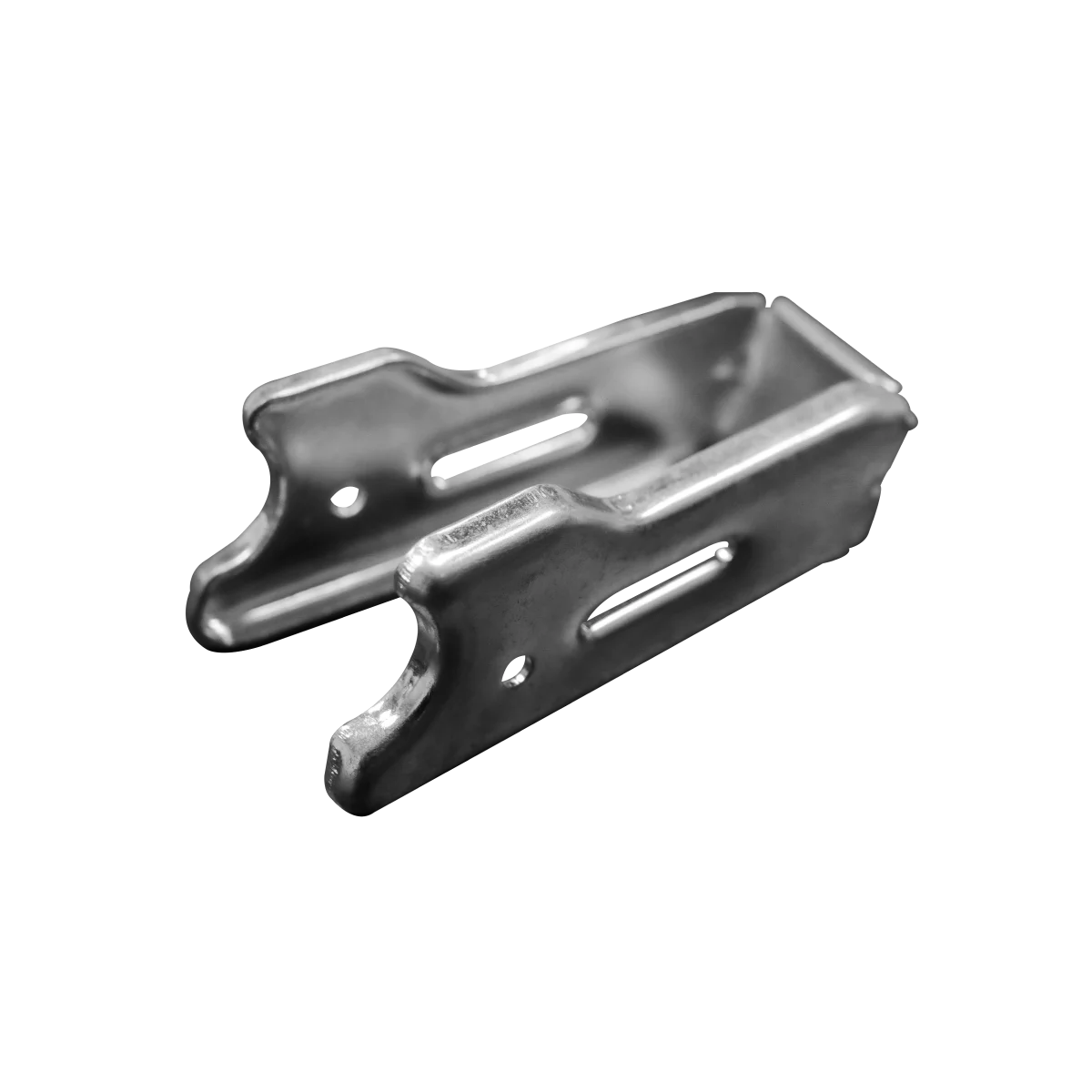

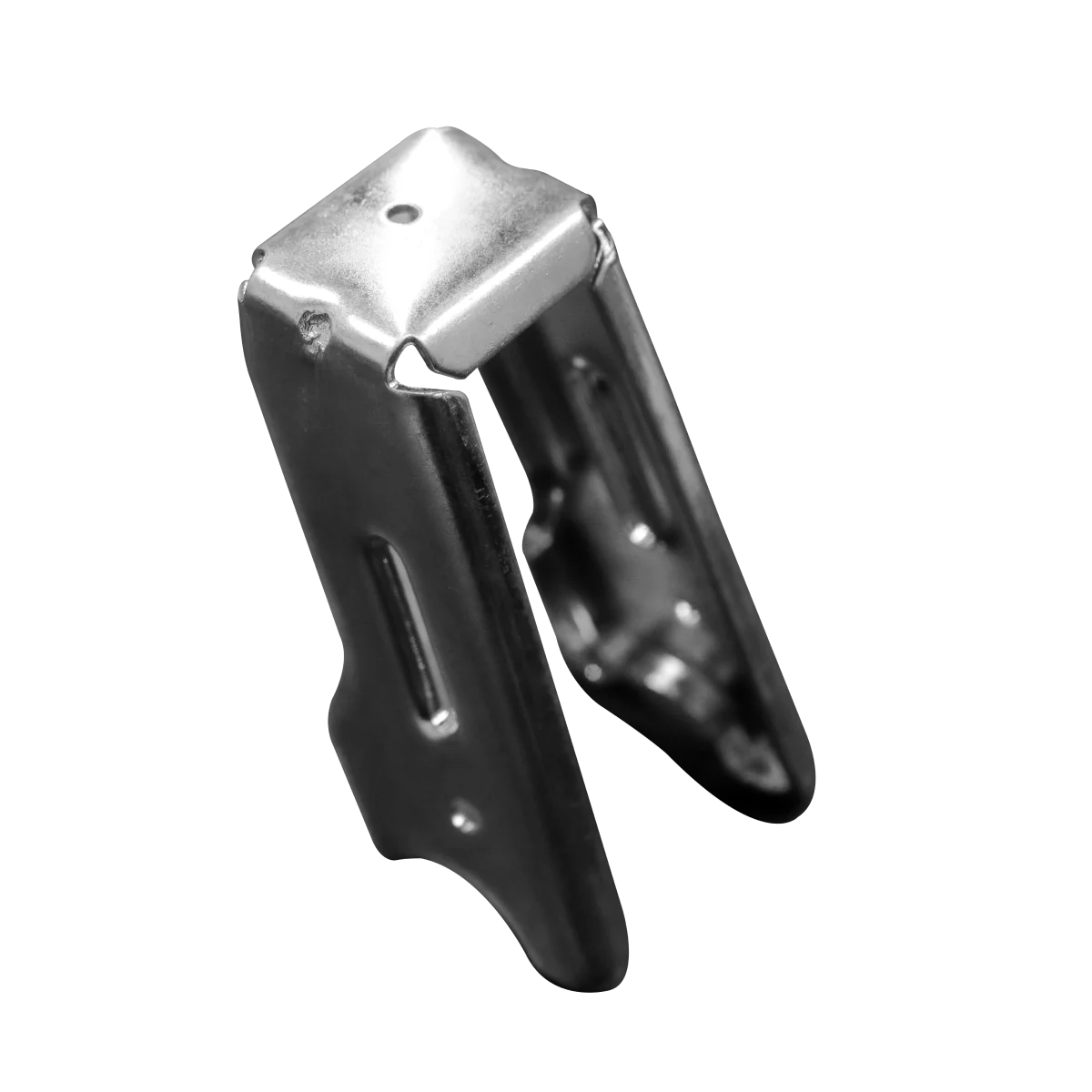

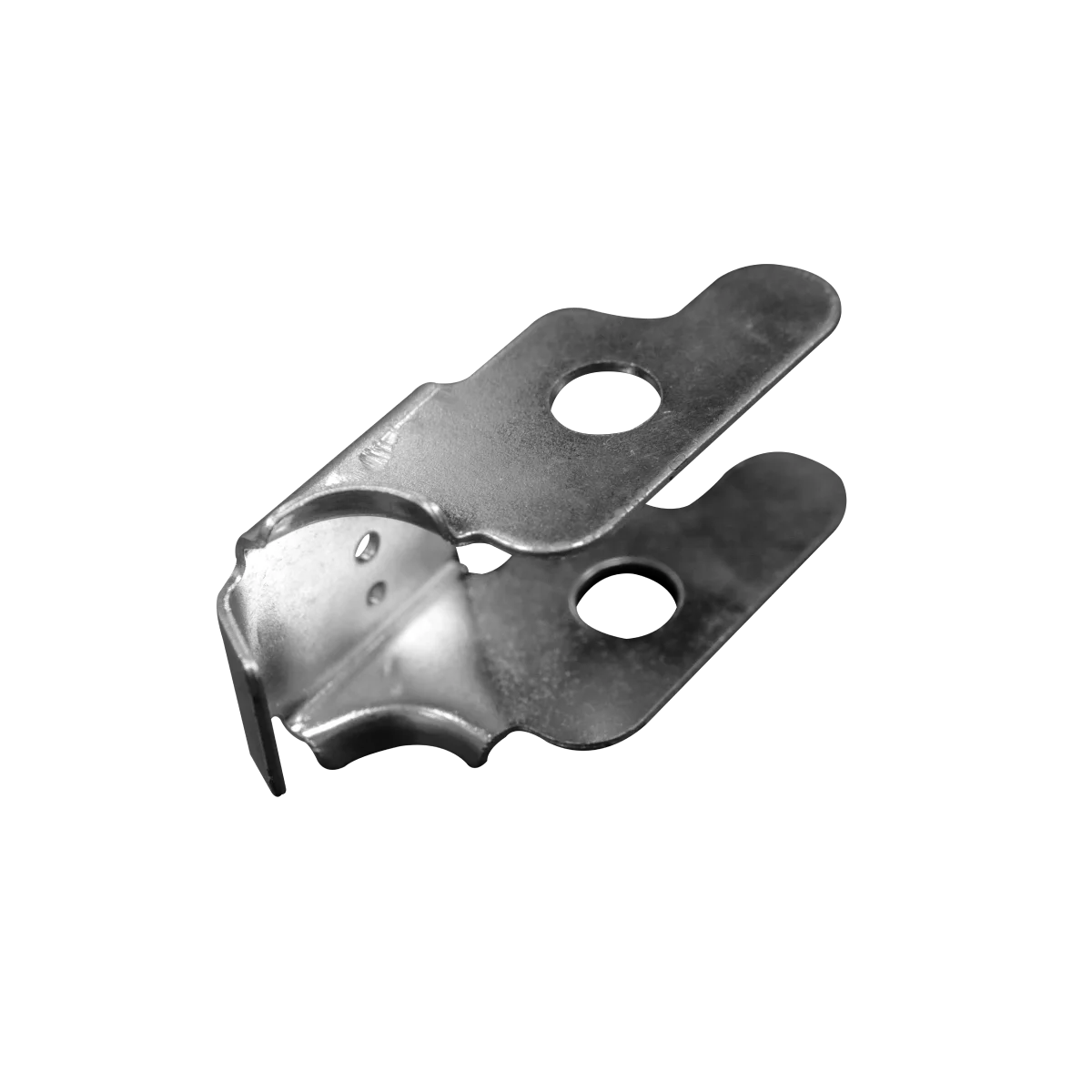

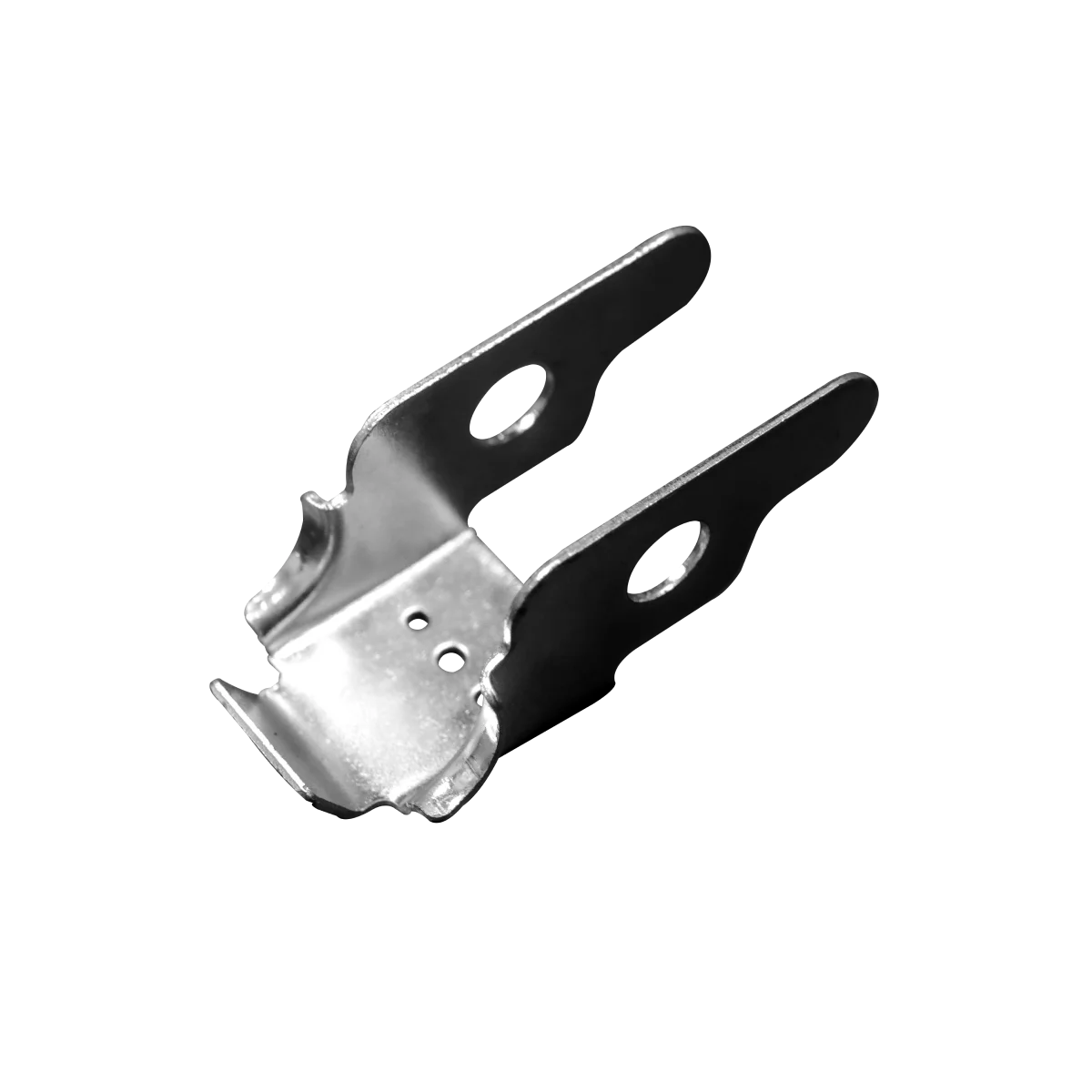

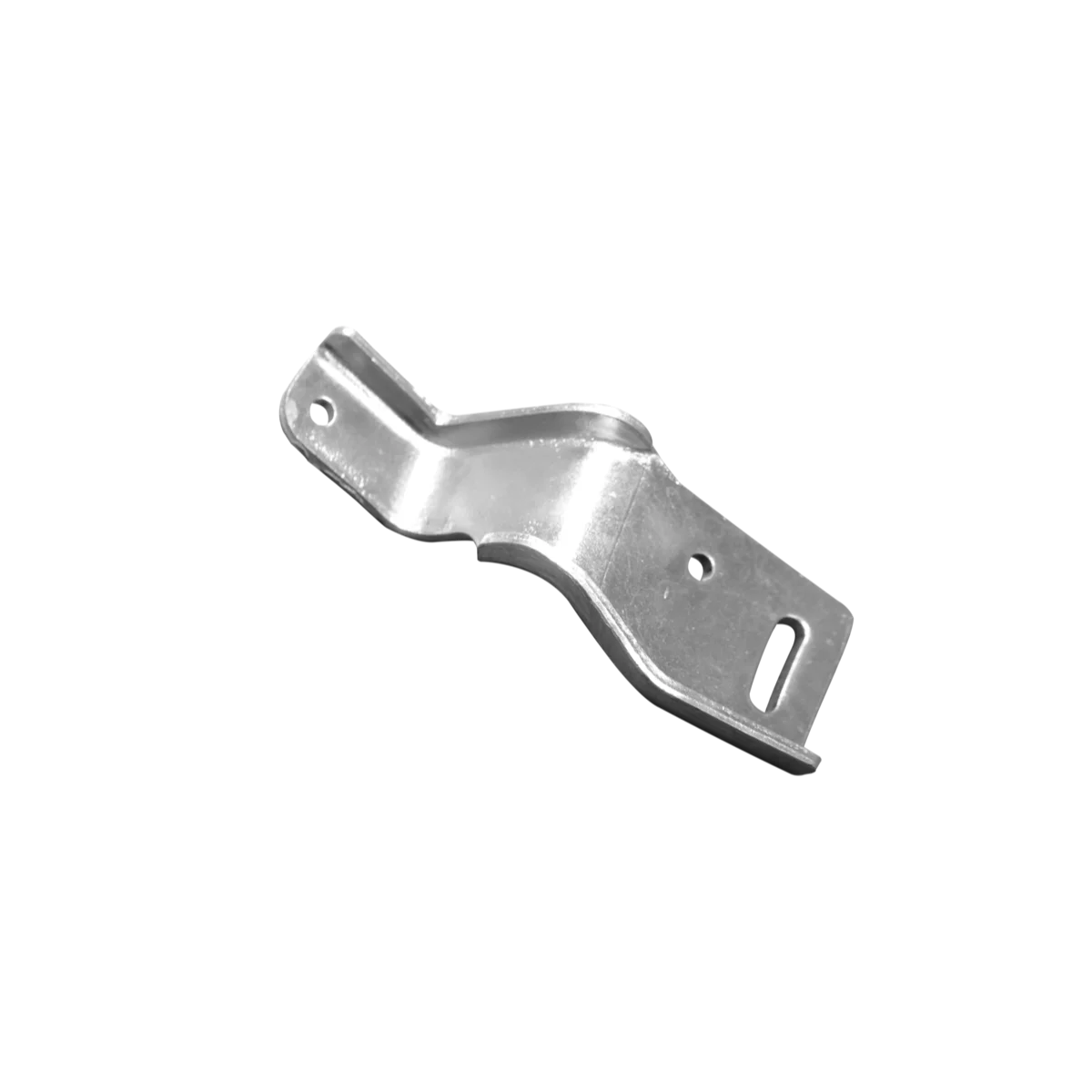

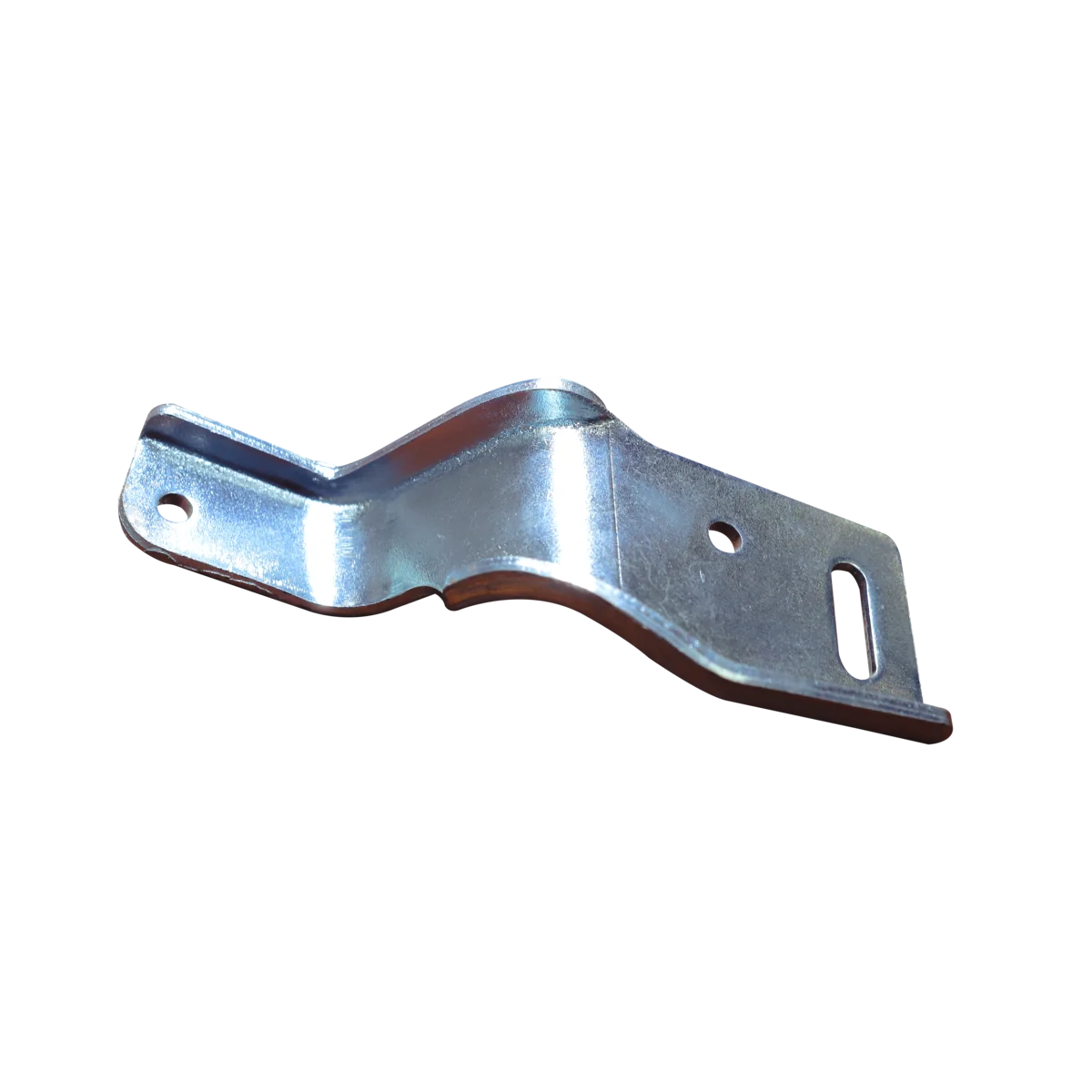

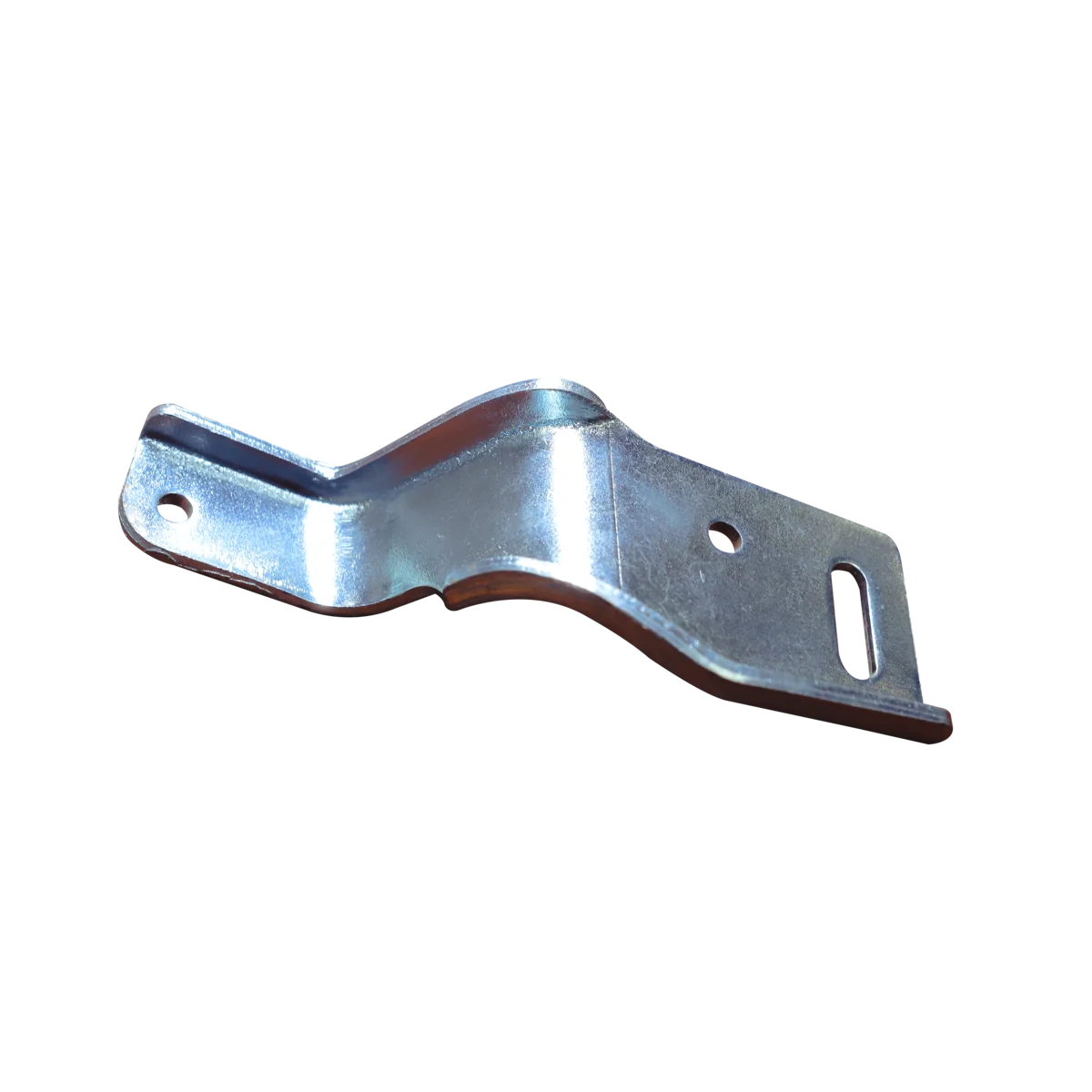

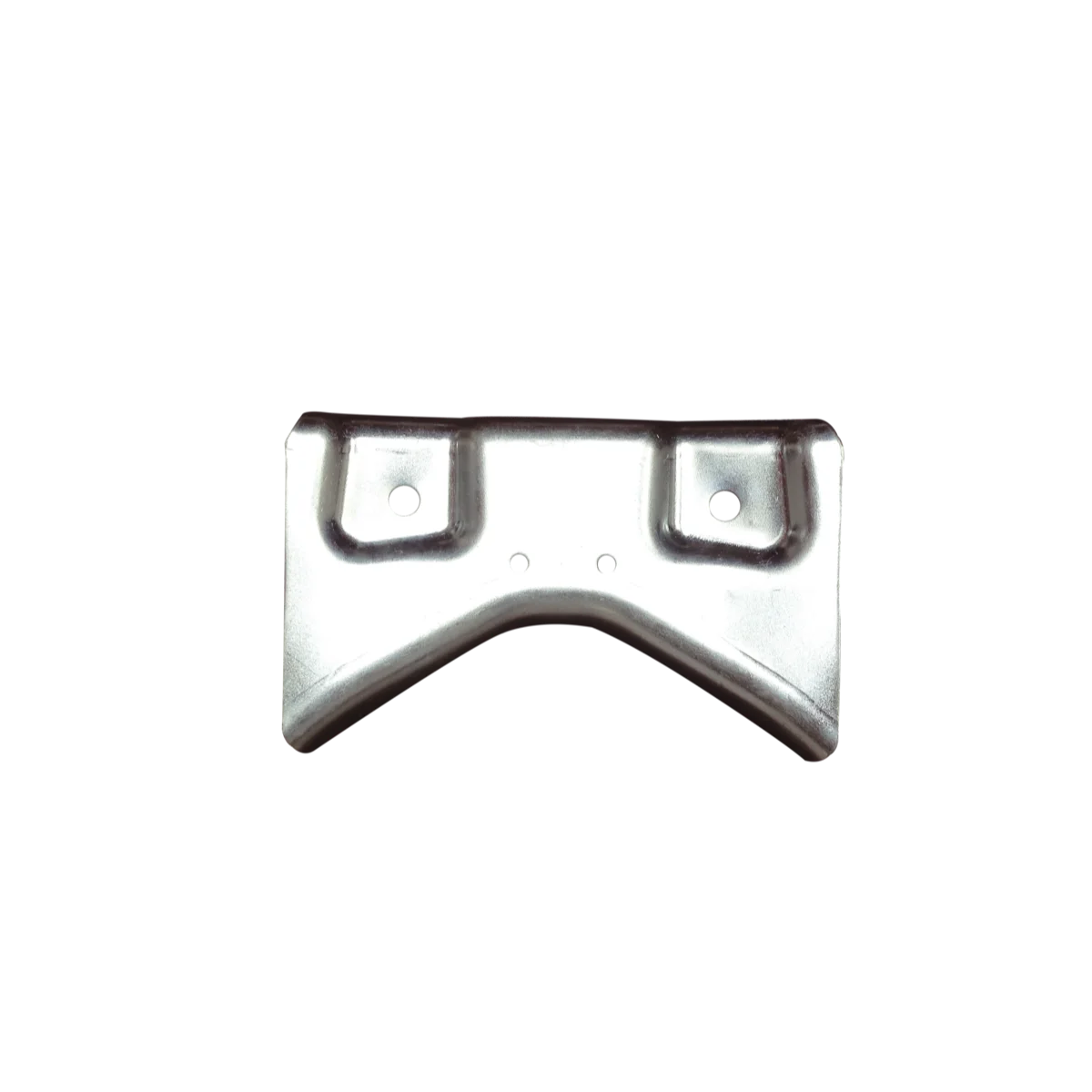

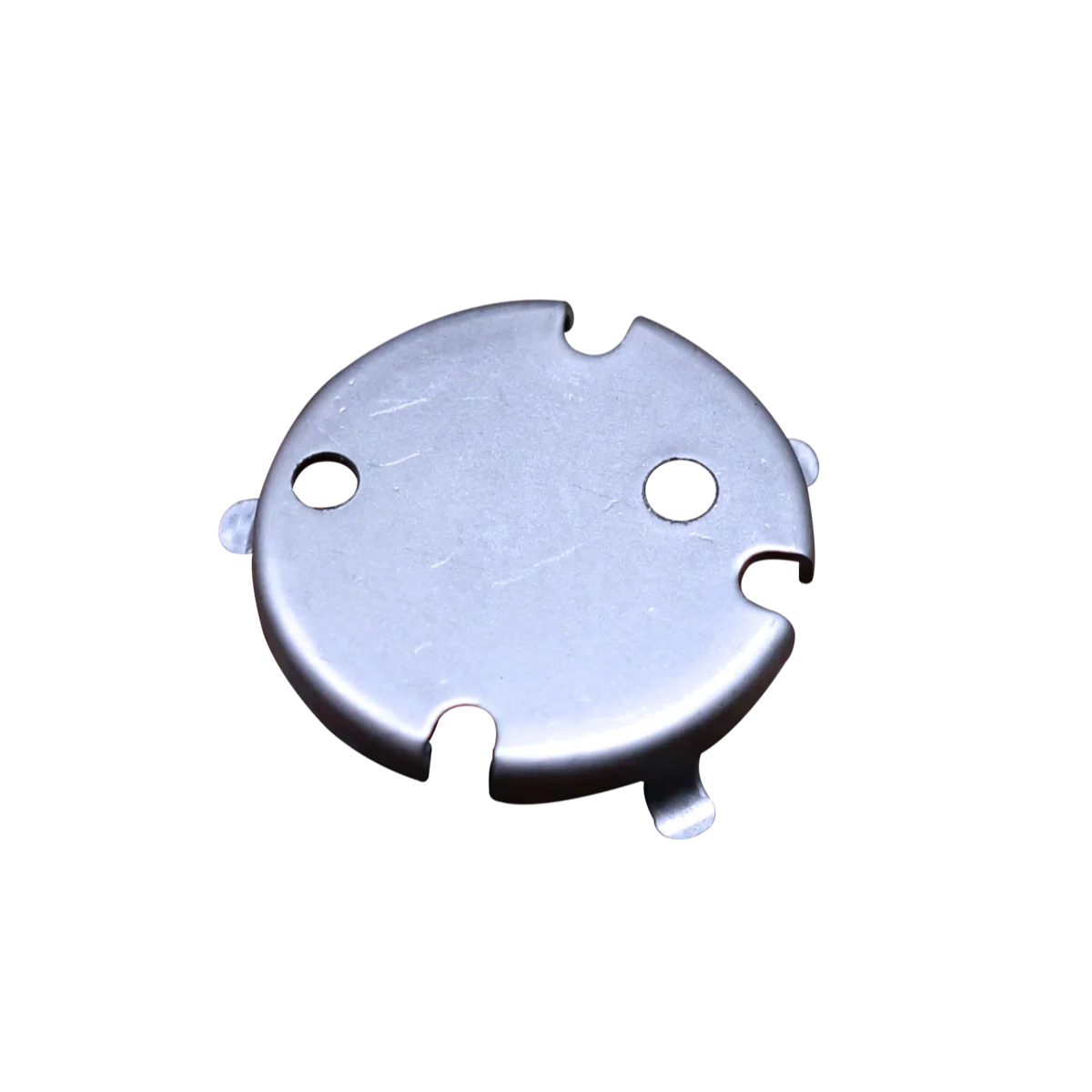

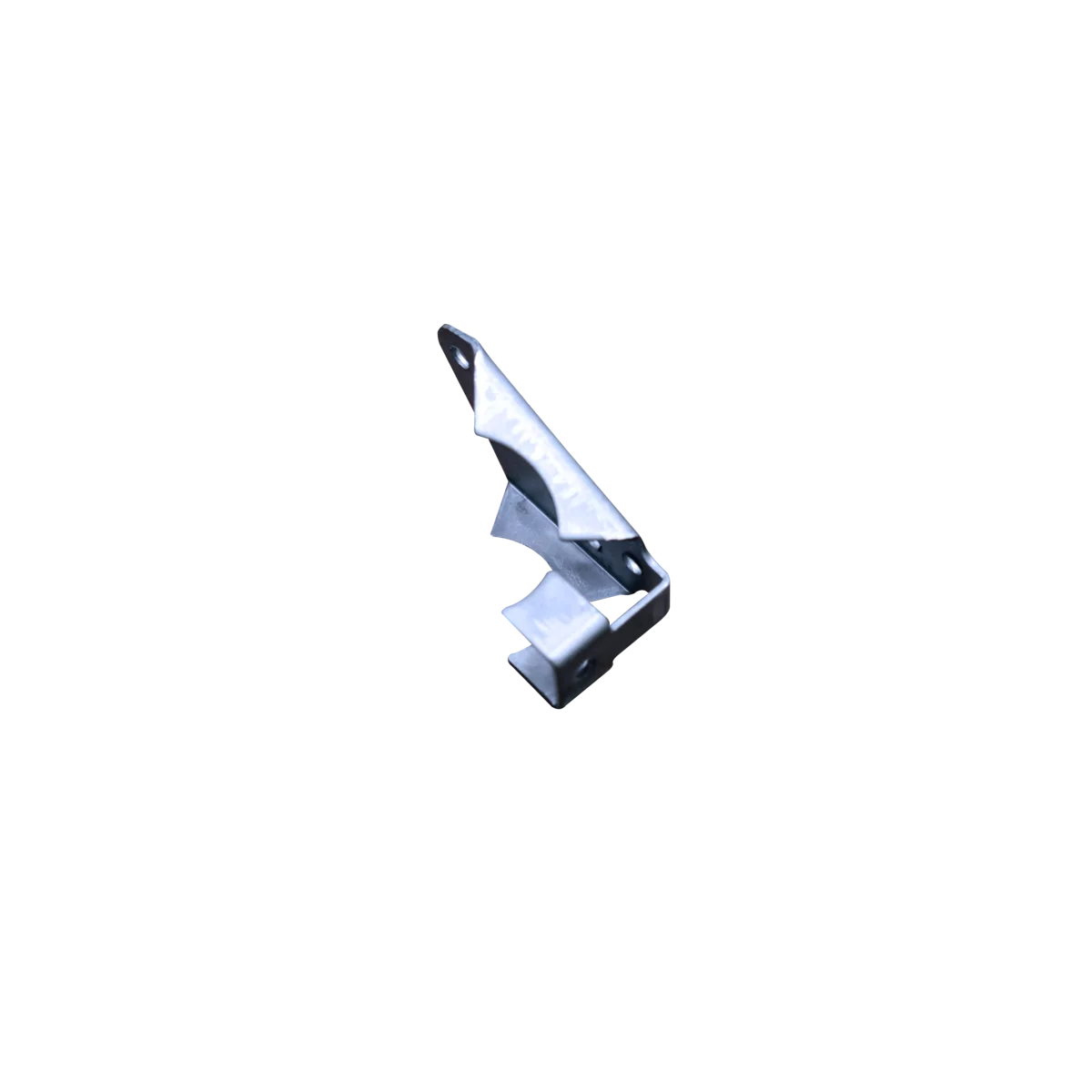

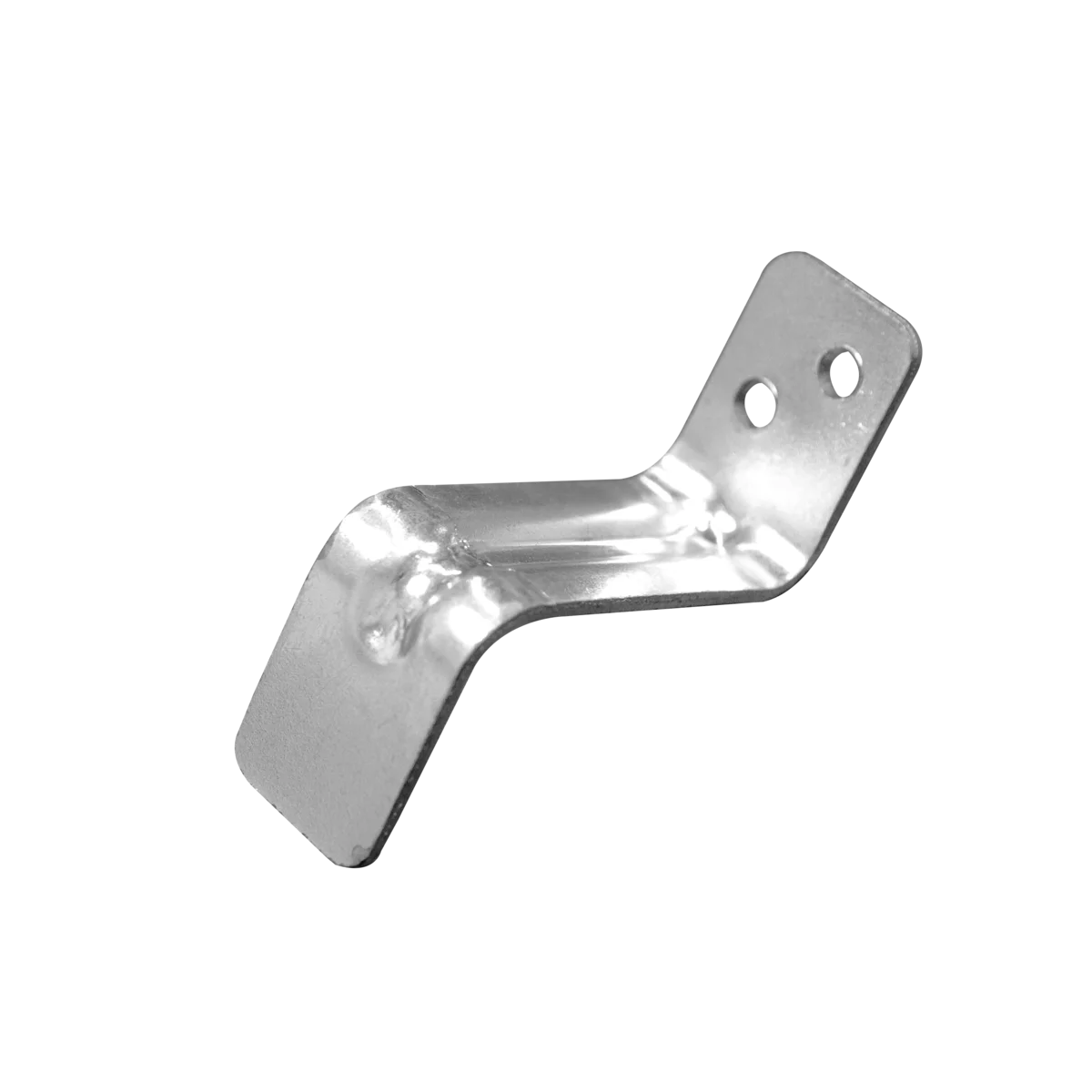

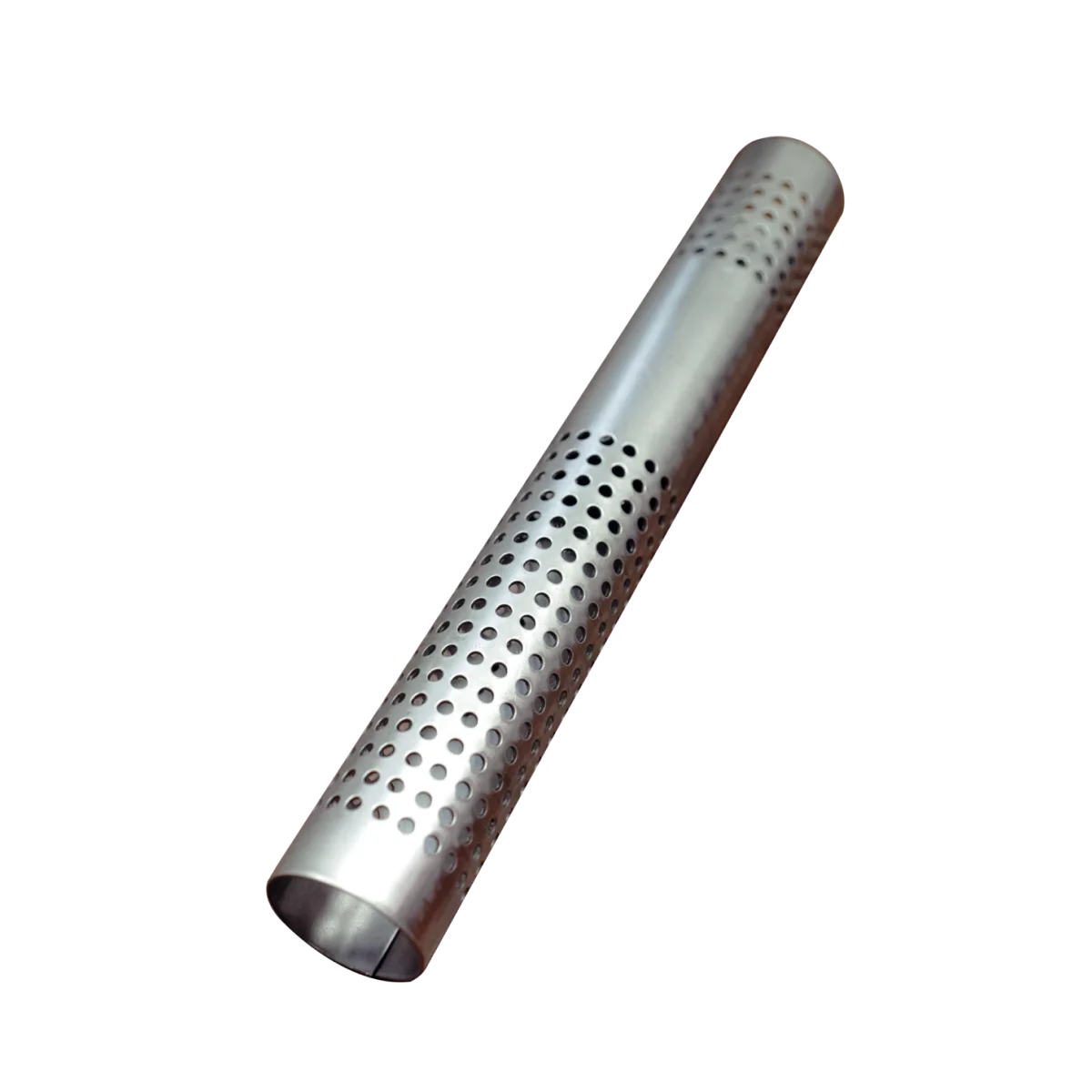

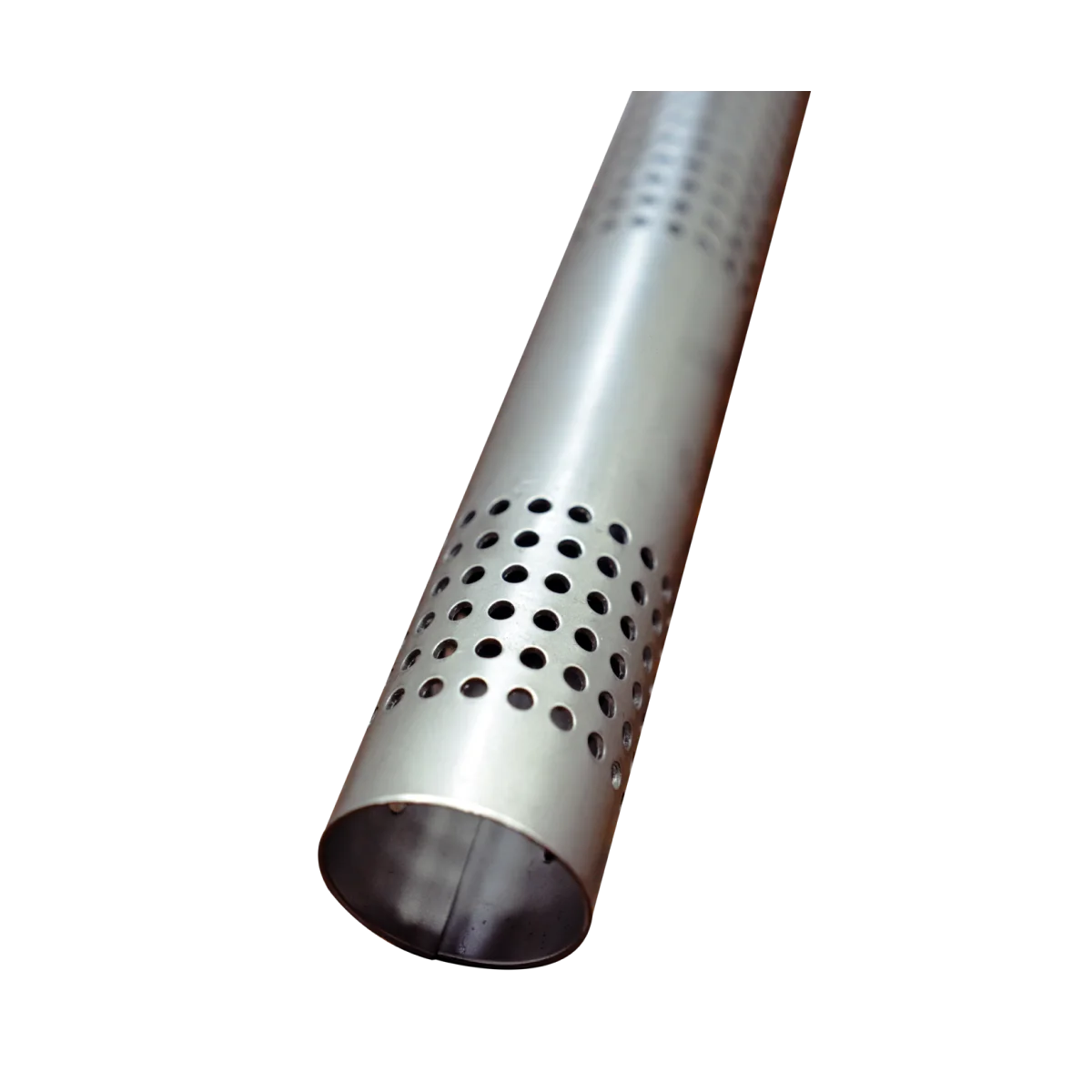

Sheet Metal Pressed Components Manufacturing

We are experts in manufacturing defect-free sheet metal components with high precision and best quality at optimal cost.

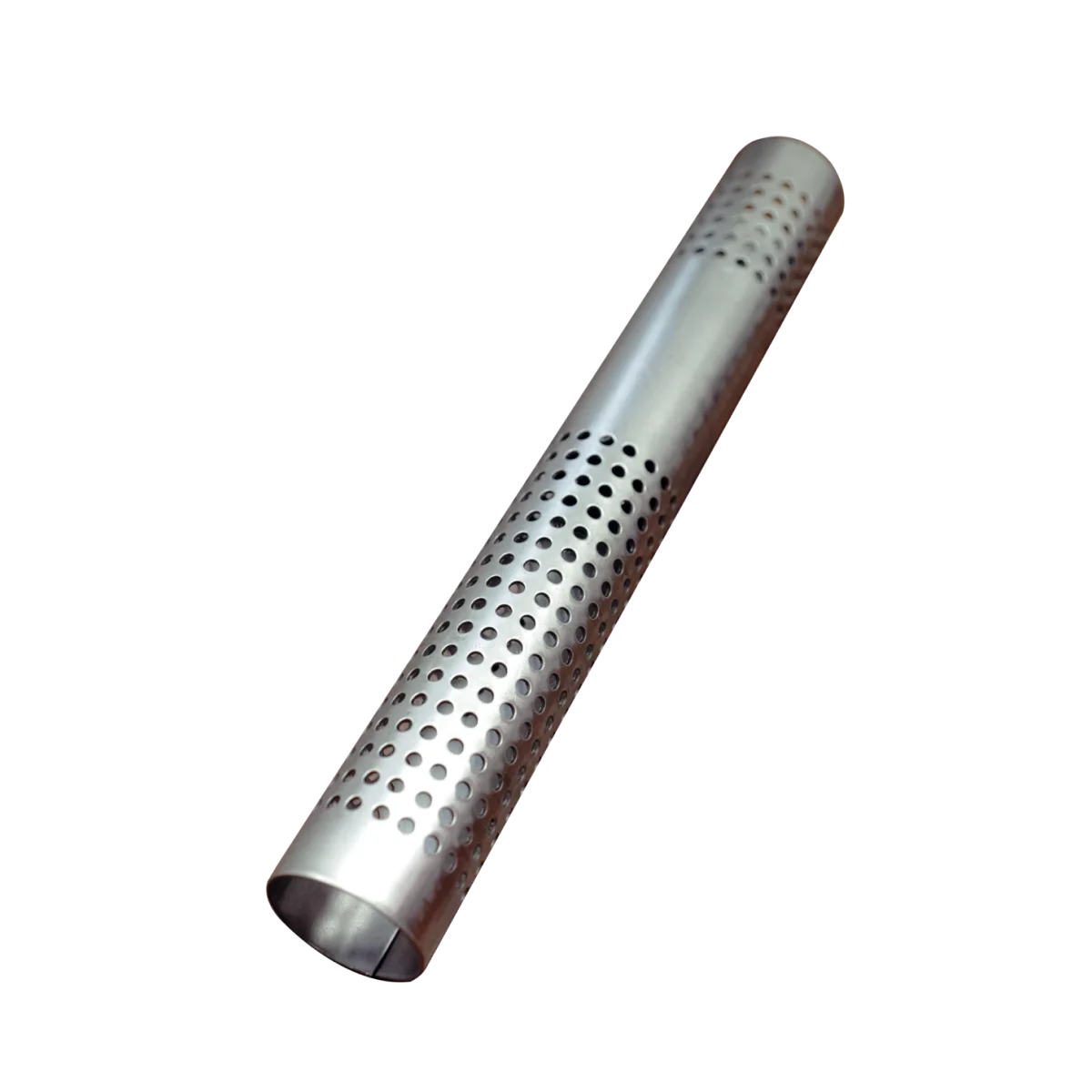

Sheet Metal Components Welding Sub-Assemblies

Specializing in premium welded sub-assemblies, we deliver durable and reliable sheet metal solutions for all engineering applications.

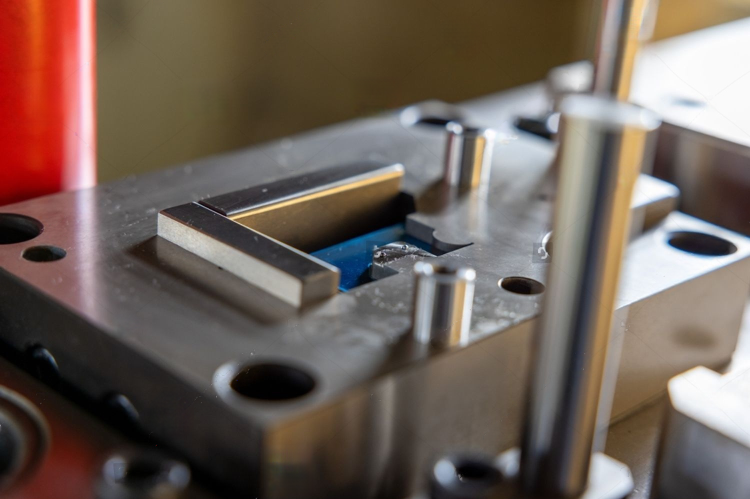

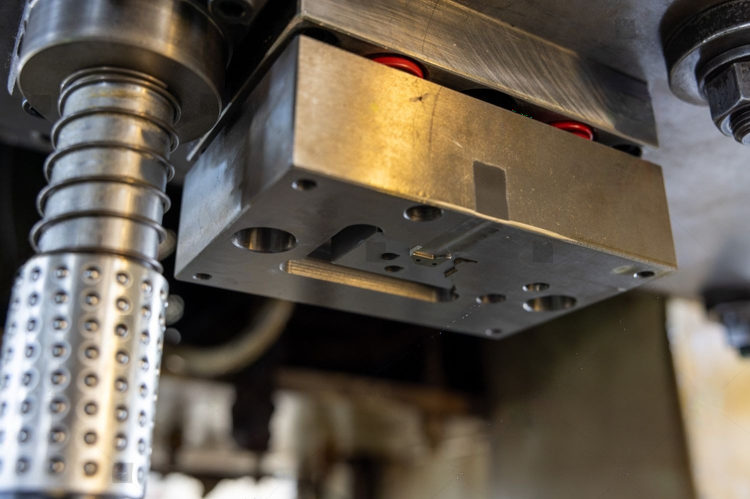

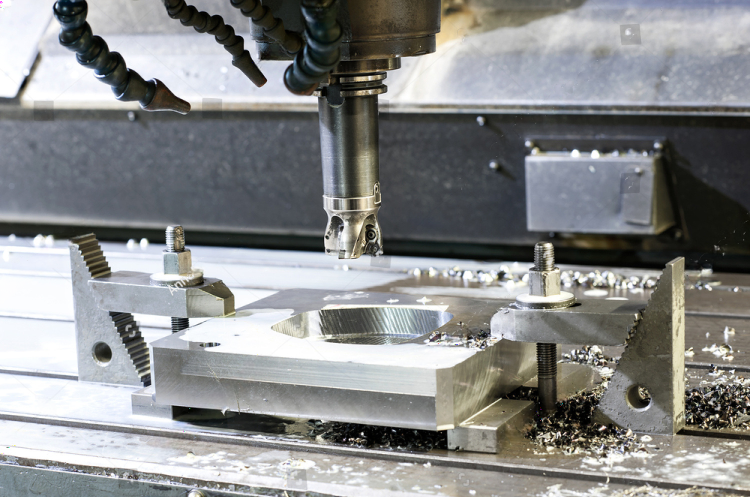

Design and Manufacturing of Dies and Tools for Sheet Metal Components

Our in-house die and tool manufacturing ensures customized, high-precision tooling solutions.

Industries We Serve

Our Commitment

Zero Defects

MicroTech Pressings, an ISO-9001 certified leader in sheet metal manufacturing, is on the path to Six Sigma, aiming for “0”PPM to support our customers’ zero defects goals. Our commitment to quality, continuous improvement, and operational excellence ensures we are the ideal partner for achieving flawless production outcomes, making us a trusted ally in your quest for perfection.

100% Parts Traceability

MicroTech Pressings leads in automotive sheet metal manufacturing by solving a key issue: Parts Traceability. Our real-time management system offers full traceability from raw material to dispatch, even to each part’s heat number. This ensures top accountability and quality, meeting strict precision and reliability standards. Clients enjoy peace of mind with detailed tracking of their parts’ journey.

Customization and Flexibility

MicroTech Pressings excels in flexibility, adapting to the volatile automotive sheet metal industry. With an agile shop floor, regular reviews, precise inventory management, and augmented production capacity, we meet unexpected demands and customizations seamlessly. Our approach ensures reliability and responsiveness, keeping us ahead in meeting client needs efficiently.

Top Notch QCDS

MicroTech Pressings leads in QCDS – Quality, Cost, Delivery, Service – ensuring automotive OEMs receive unparalleled support. Our dedication to excellence in each area, from stringent quality controls and cost-effective solutions to timely deliveries and exceptional service, positions us as a top choice for partners aiming for superior performance and reliability in sheet metal manufacturing.

Production

Efficiency

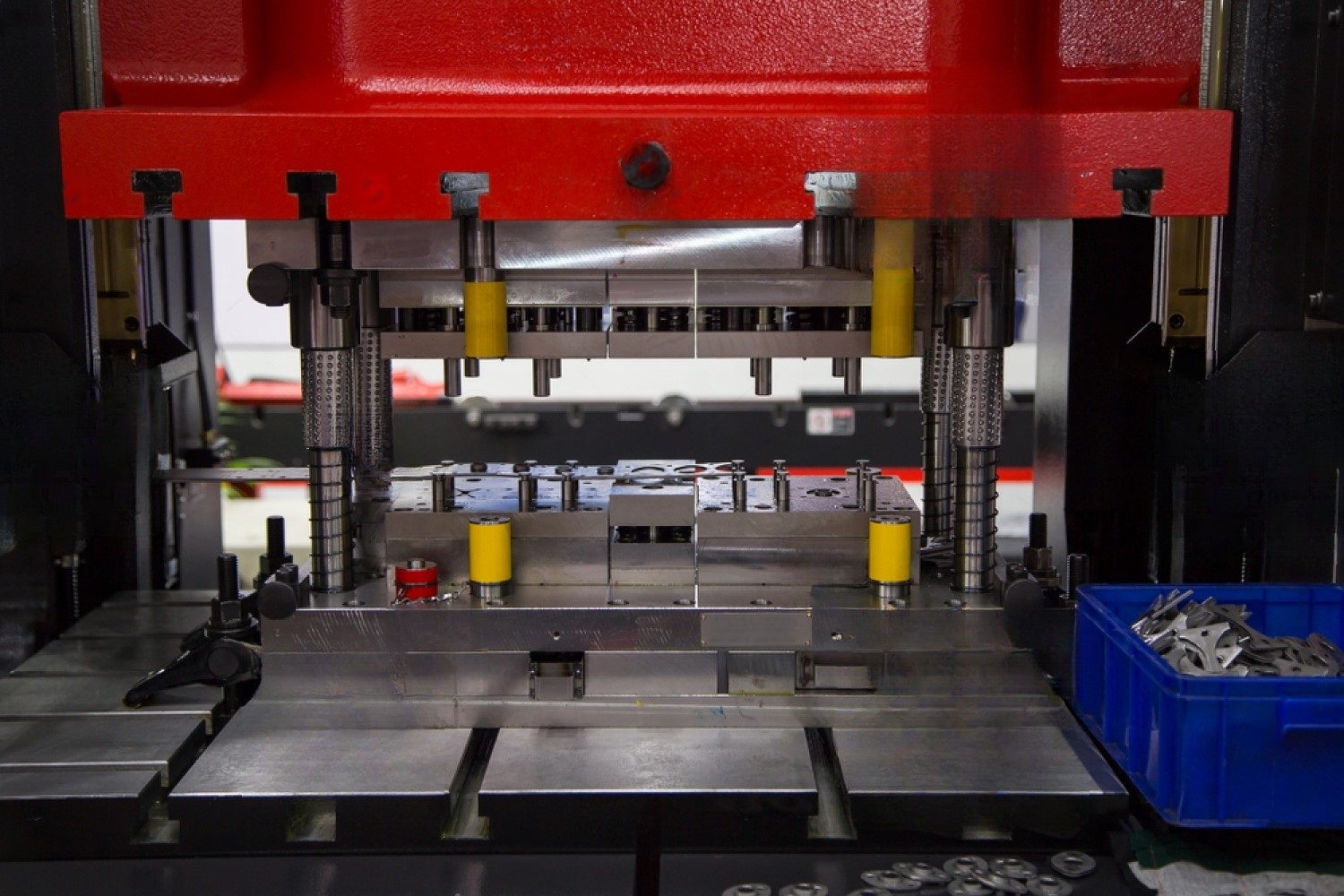

Inefficiencies in production can lead to delays and increased costs. Our facility, equipped with 11 power presses, advanced coil feeders, and specialized tools, enables high-capacity, precise metal forming and stamping. Our use of ERP systems and Industry 4.0 technologies enhances process control and transparency, further improving efficiency.

Sustainability

Increasing environmental regulations pose challenges for manufacturers. We are committed to sustainable practices, incorporating energy-efficient processes and waste reduction initiatives, contributing positively to the environment and complying with regulations.

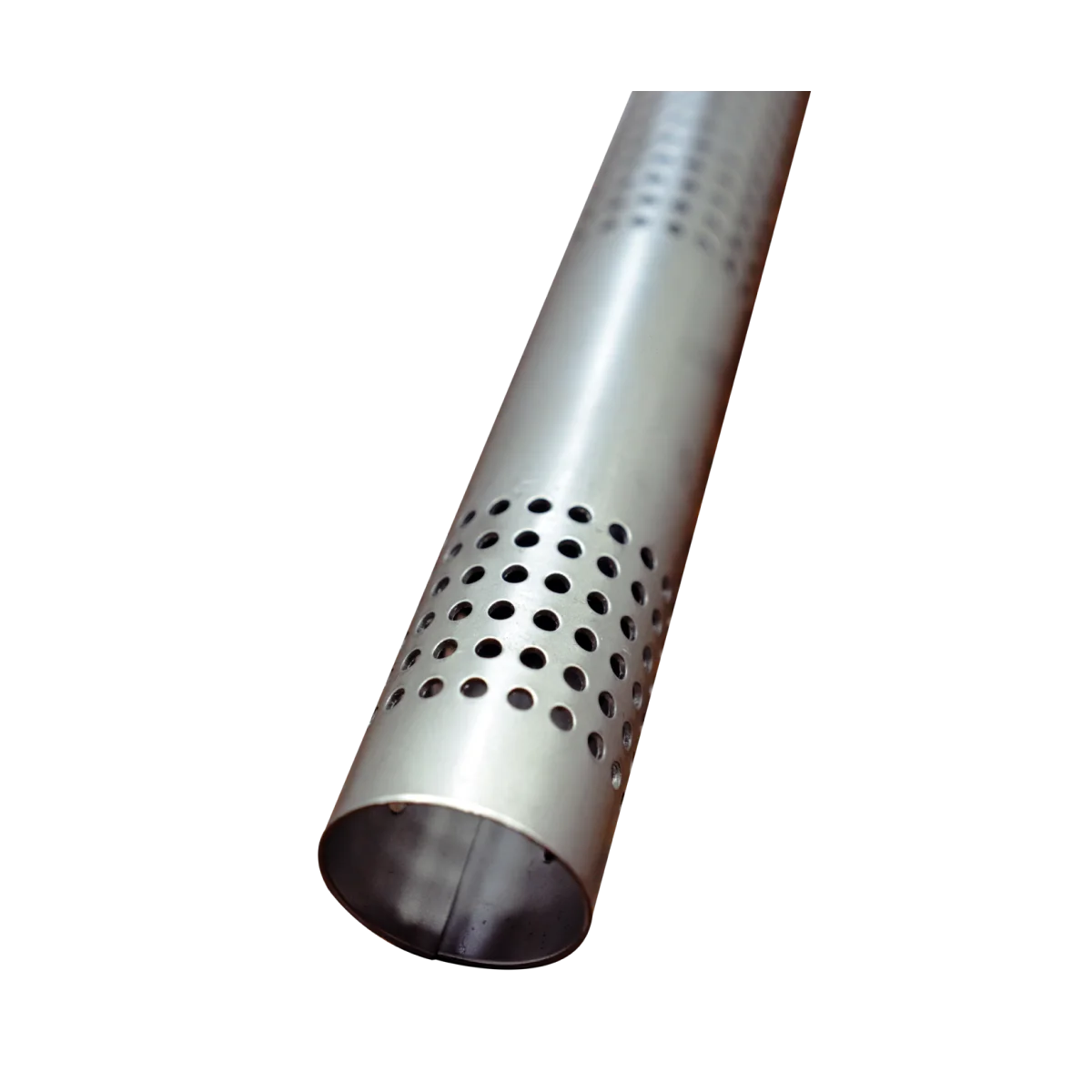

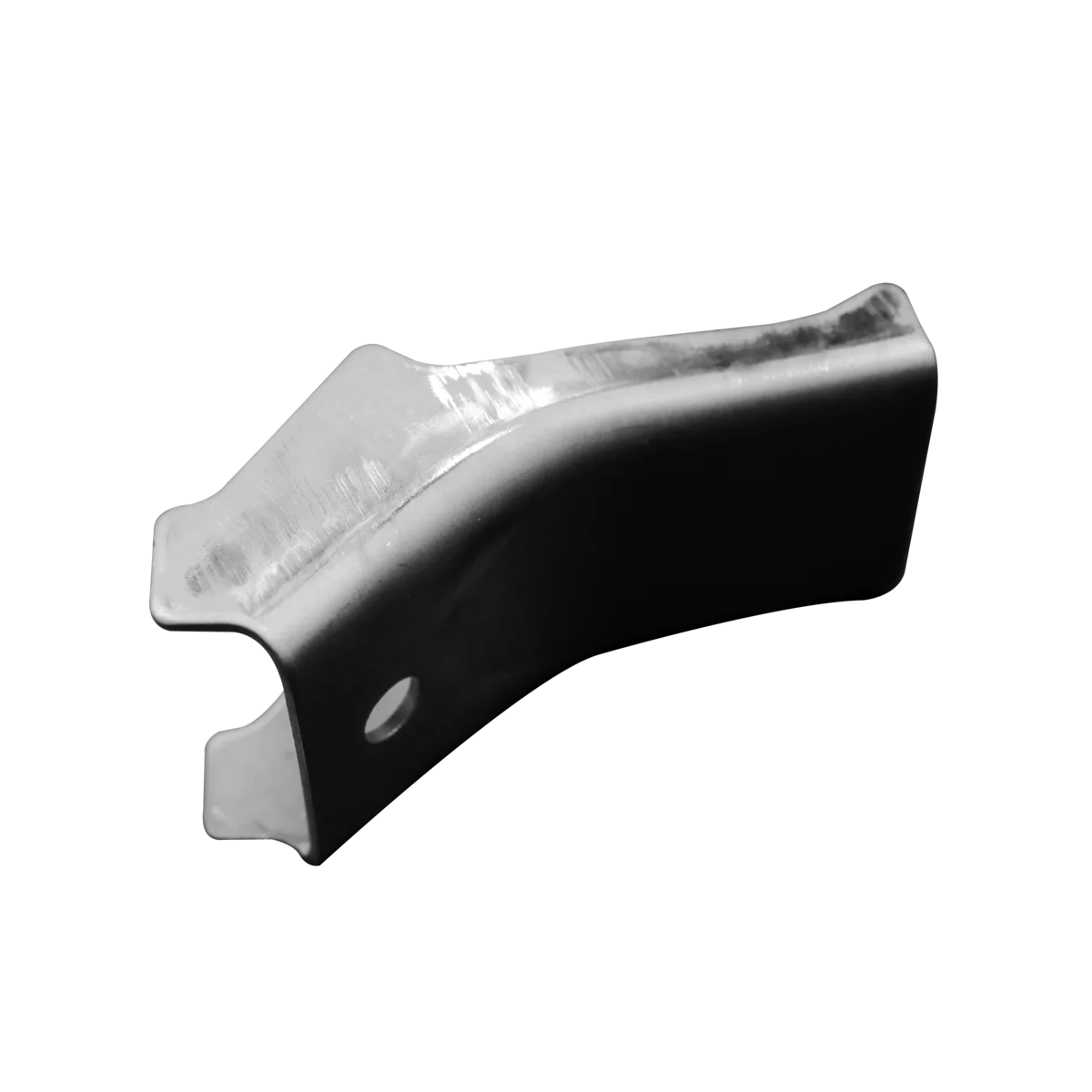

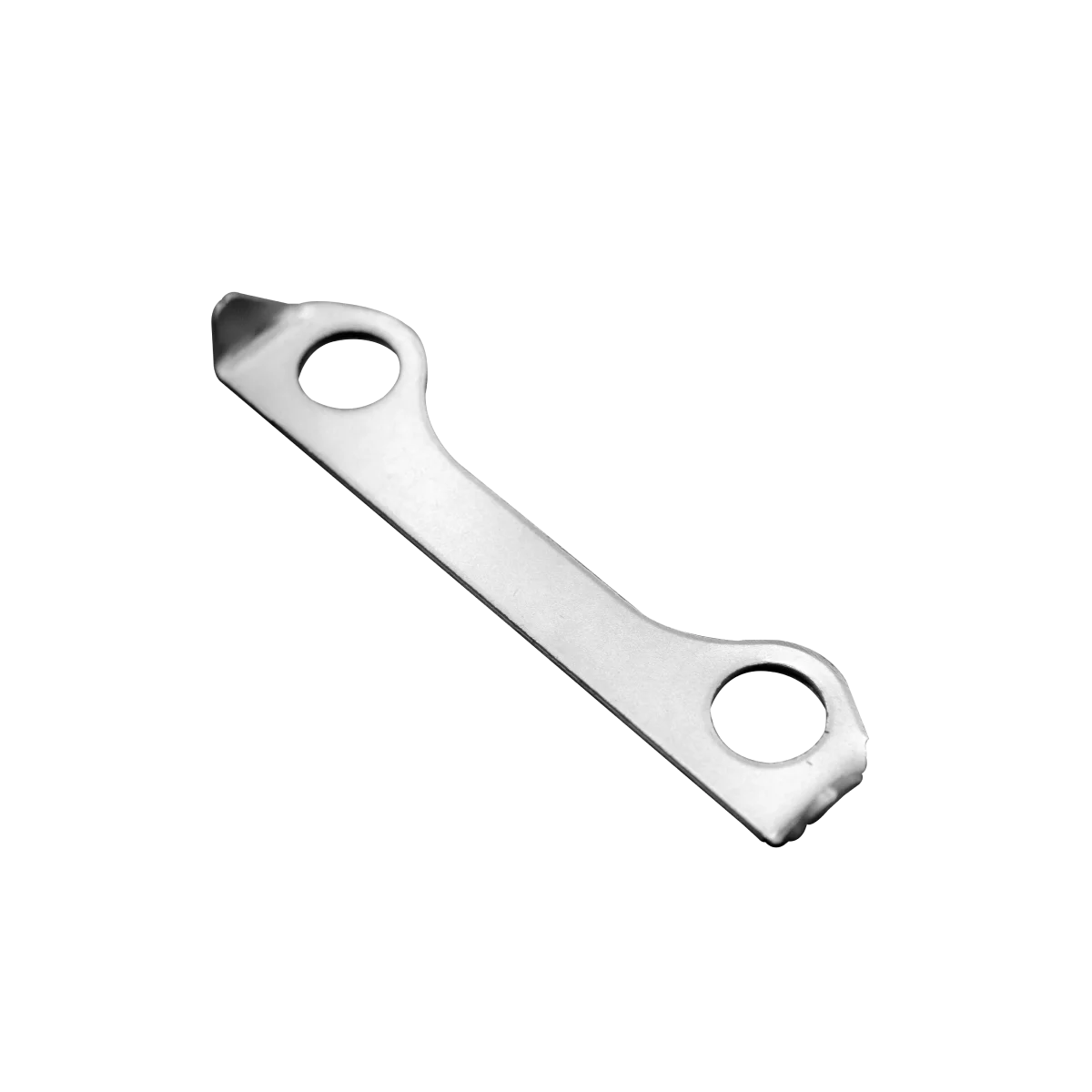

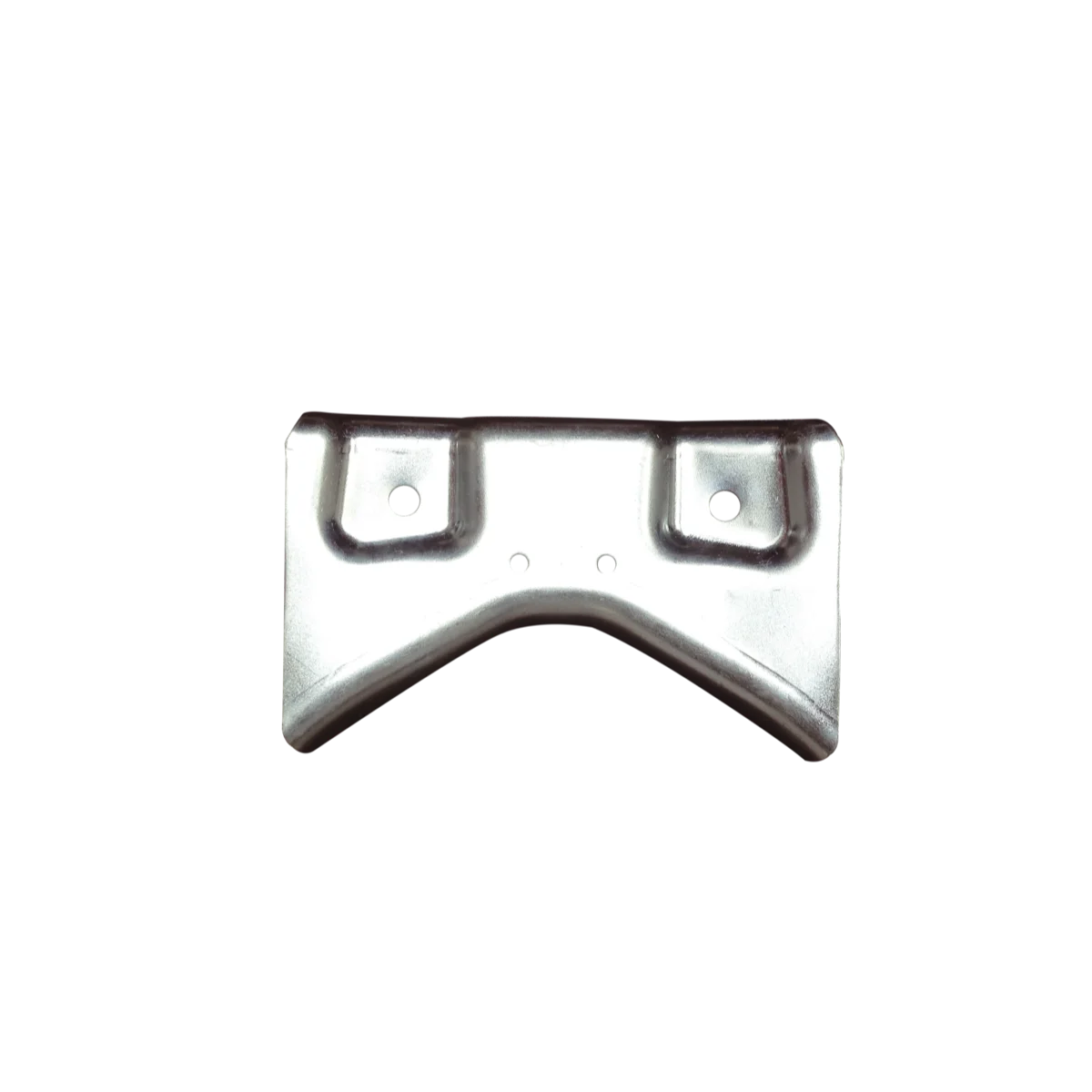

Wide Range of Products for

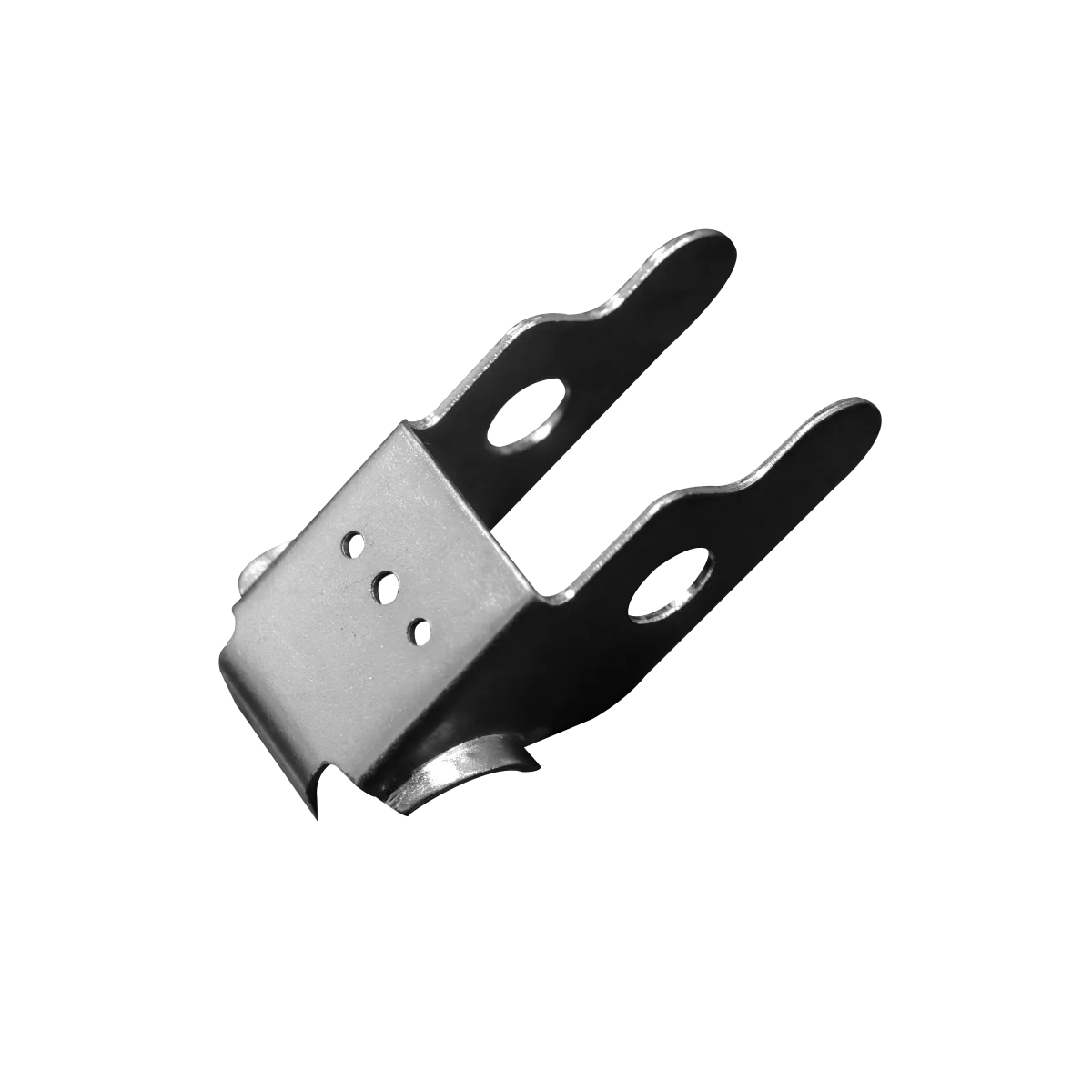

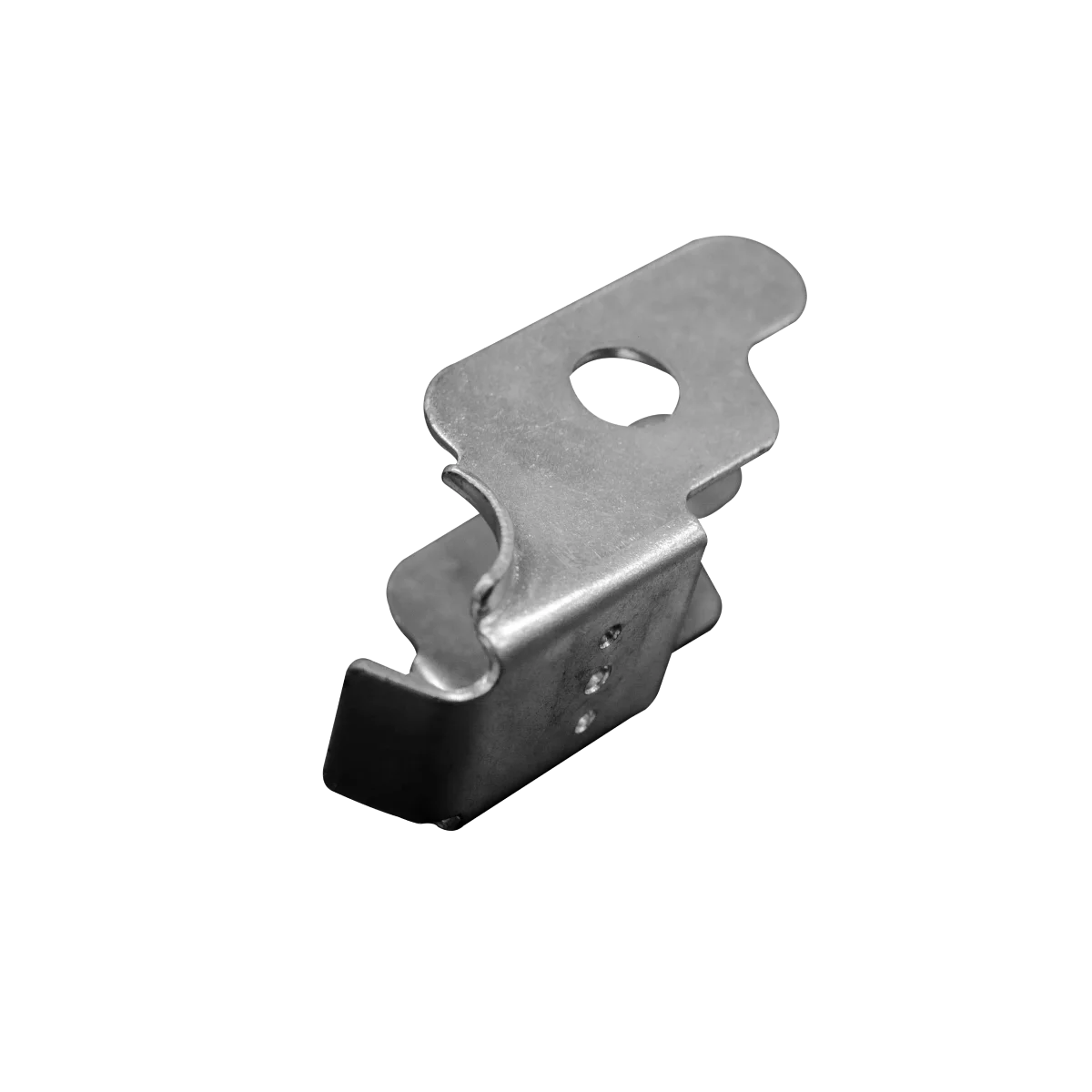

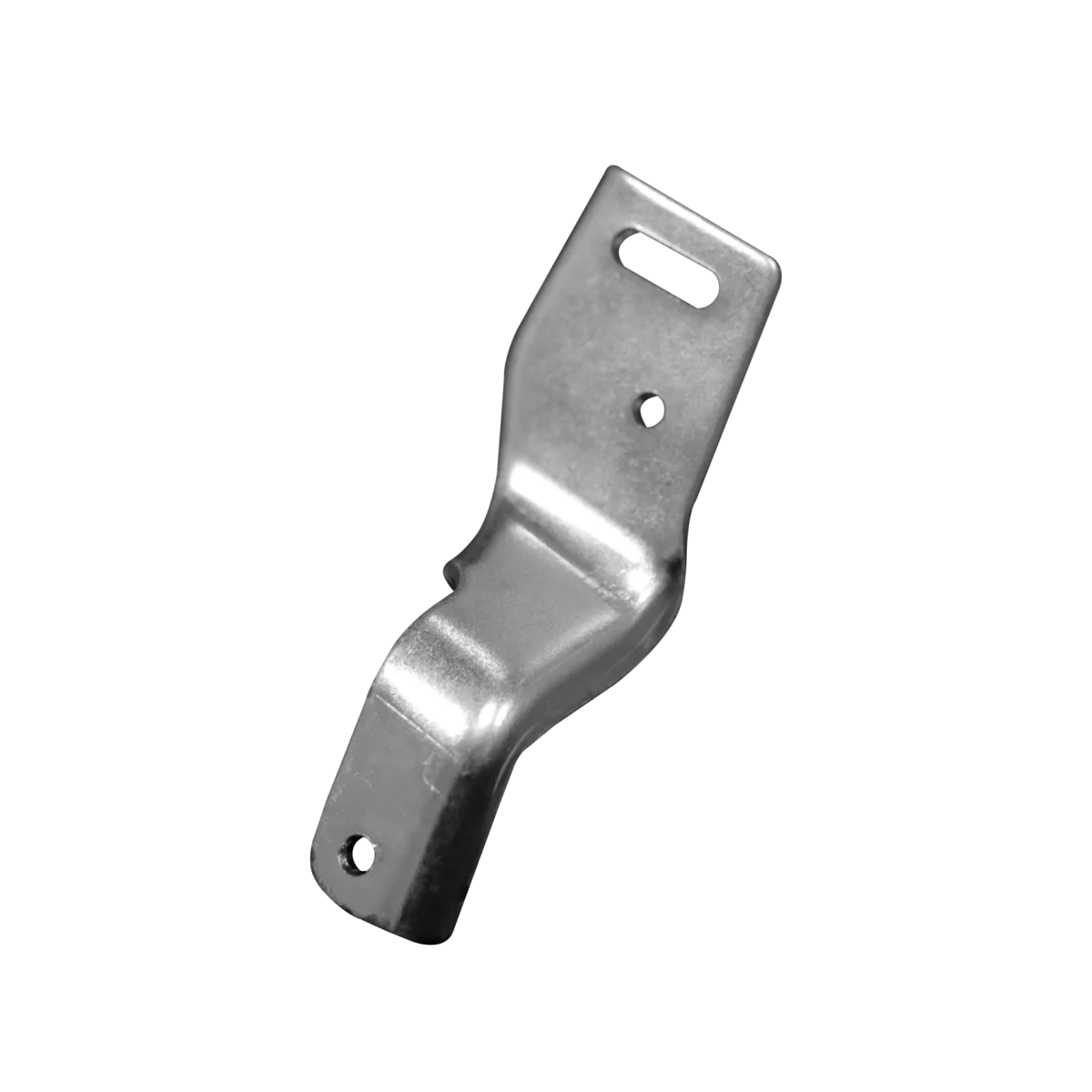

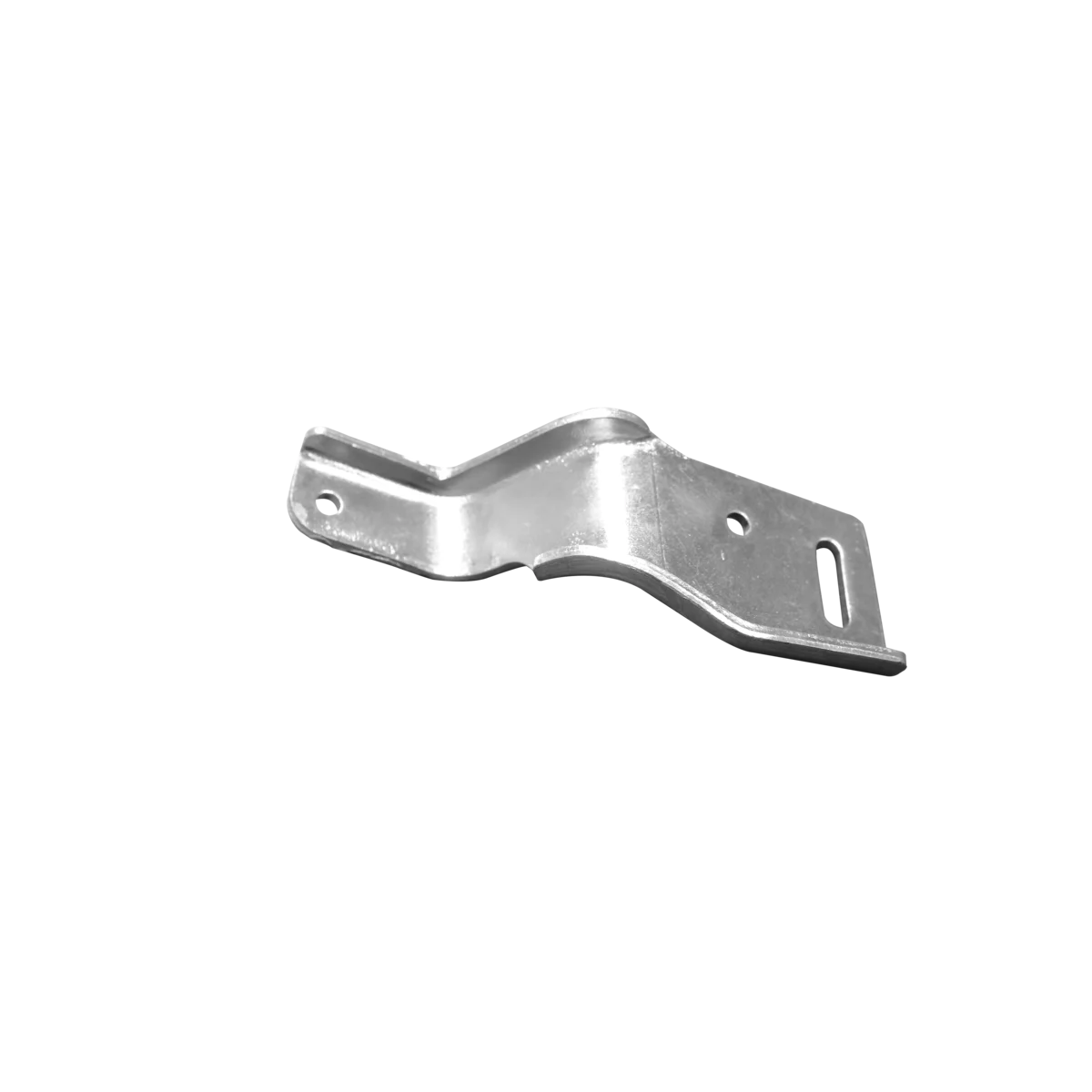

Product 53

Product 51

Product 31

Product 30

Product 29

Product 27

Product 49

Product 47

Product 43

Product 41

Product 40

Product 38

Product 54

Product 52

Product 50

Product 46

Product 44

Product 36

Product 23

Product 15

Product 57

Product 56

Product 55

Product 54

Product 53

Product 52

Infrastructure

MicroTech Pressings features a modern infrastructure with 11 power presses (80 Ton to 250 Ton), advanced coil feeders, and a range of precision tool room machines. Our facility also includes essential equipment like a 160kVA diesel generator, MIC and ARC welding machines, and forklifts, ensuring high-quality manufacturing and operational efficiency.

MicroTech Pressings’ superior quality stems from our exclusive raw material storage and advanced inventory management, ensuring lot-wise traceability. This meticulous approach guarantees the integrity of materials and finished products, allowing us to swiftly identify and address any quality issues. Our commitment to transparency and precision in tracing components from source to dispatch assures customers of consistent, high-quality sheet metal parts, reinforcing our role as a trusted partner in the automotive industry.

MicroTech Pressings’ shop floor is outfitted with an impressive line-up of specialized machinery to ensure the highest quality in sheet metal automotive parts. Our arsenal includes transfer presses, hydraulic presses, servo presses, punch presses, turret punch presses, and progressive die stamping machines, ranging from 50 to 250 tons. This diverse range of equipment enhances our flexibility and capability, allowing us to produce a wide variety of superior sheet metal components for the automotive, home appliances and other industries, meeting exacting standards with unparalleled precision.

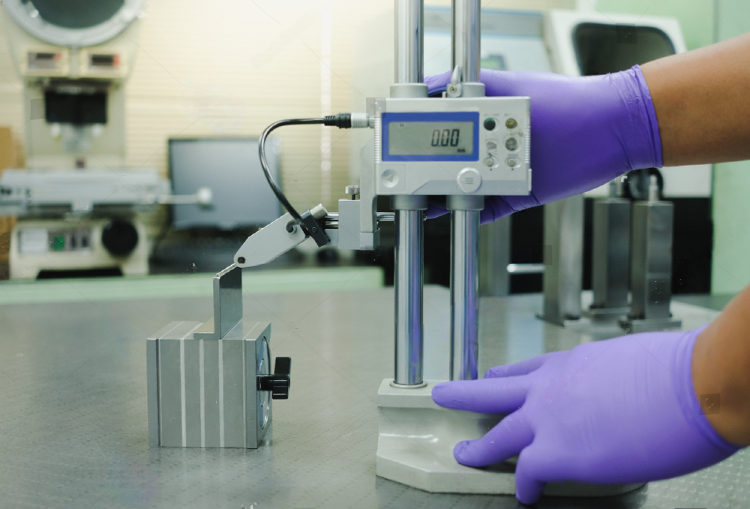

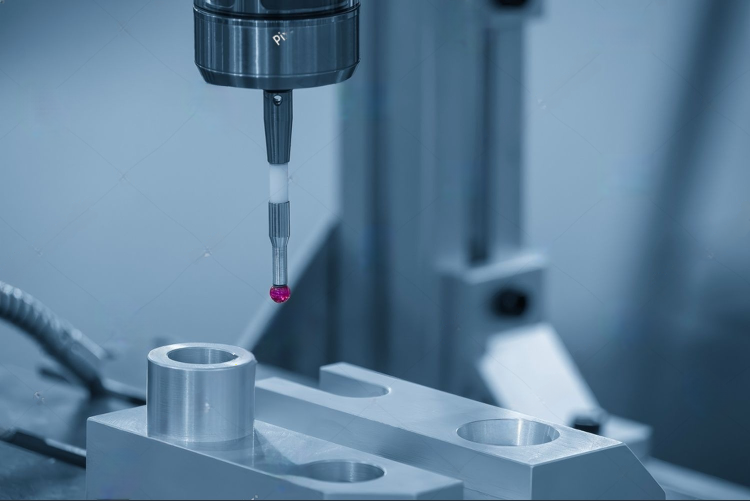

MicroTech Pressings employs a mix of standard and modern quality processes, including visual inspection, dimensional measurement, hardness testing, at times CMM, 3D scanning, and optical systems (by engaging 3rd party service providers), to ensure top-quality automotive parts. This comprehensive approach combines traditional and advanced techniques, enabling precise defect detection and dimensional accuracy. Our commitment to integrating cutting-edge inspection technologies supports our customers’ goals for zero defects and high-quality products, making us a trusted partner in automotive manufacturing.

MicroTech Pressings employs a mix of standard and modern quality processes, including visual inspection, dimensional measurement, hardness testing, at times CMM, 3D scanning, and optical systems (by engaging 3rd party service providers), to ensure top-quality automotive parts. This comprehensive approach combines traditional and advanced techniques, enabling precise defect detection and dimensional accuracy. Our commitment to integrating cutting-edge inspection technologies supports our customers’ goals for zero defects and high-quality products, making us a trusted partner in automotive manufacturing.

Our Capabilities

The company’s expertise in precision engineering and commitment to quality ensure that every product meets the stringent standards of the automotive sector.

Advanced

Quality Control

MicroTech Pressings stands out in the automotive sector with its sophisticated quality control protocols. By integrating diverse quality inspection equipment and systems, we ensure that each component meets the stringent precision and reliability requirements of the automotive industry. This commitment to advanced inspection techniques underpins their capability to consistently achieve zero defects in their products.

Specialized

Tooling Expertise

At the heart of MicroTech Pressings’ operations is its extensive use of specialized tools and dies, such as progressive, transfer, and compound dies. This arsenal of precision tooling enables the company to tackle a broad spectrum of manufacturing challenges, producing high-quality, defect-free components that precisely meet the specifications of automotive clients. Our tooling expertise is a critical factor in their ability to deliver custom solutions and maintain high standards of quality.

Manufacturing

Flexibility & Innovation

MicroTech Pressings demonstrates exceptional flexibility and innovation in manufacturing, leveraging a variety of presses including transfer, hydraulic, servo, punch, and turret punch presses. This diverse machinery portfolio, coupled with a commitment to technological advancement and continuous process improvement, allows for the efficient production of a wide range of sheet metal parts. Such versatility is key to adapting to the evolving demands of the automotive industry, ensuring both quality and efficiency in production.

Awards & Recognition

ISO 9001 : 2015 Certified

MicroTech Pressings, an ISO 9001 : 2015 certified leader progressing towards Six Sigma and aiming for 0PPM, is committed to delivering zero-defect sheet metal parts to automotive OEMs. Our pursuit of IATF 16949 compliance underscores our dedication to quality, ensuring we meet the highest industry standards. By prioritizing precision, we guarantee our partners achieve their quality objectives, enhancing product performance and customer satisfaction.

Brands with our Presence

MicroTech Pressings is honoured to have established a strong presence across numerous prestigious brands within the automotive and metal manufacturing sectors. Our unwavering dedication to excellence, reliability, and cutting-edge solutions has made us a trusted partner for industry leaders. We cherish the relationships we’ve built and are committed to delivering outstanding results that meet and exceed the expectations of our brand partners. Discover the benefits of working with MicroTech Pressings and see why so many renowned brands rely on our expertise.

Our Clients

MicroTech Pressings is proud to serve a diverse array of clients across the automotive and metal manufacturing industries. Our commitment to quality, efficiency, and innovation has earned us the trust of leading companies. We value our partnerships and continuously strive to exceed our clients’ expectations with superior products and services. Join our growing list of satisfied customers and experience the MicroTech Pressings difference.

Testimonial