Our Quality Commitment

At Microtech Pressing Private Limited, our quality commitment is the cornerstone of everything we do. We relentlessly pursue excellence, ensuring that every product meets the highest standards of precision and reliability. Our unwavering focus on quality drives us to exceed industry expectations and deliver unparalleled value to our customers.

Zero Defects

Zero Rejections

We aim for Zero Defects and Zero Rejections with a 0 PPM target. Our focus on perfection ensures reliable, defect-free products through continuous improvement and strict quality control.

Make it Right

First Time Itself

We commit to "Make it Right – First Time Itself" by delivering the Right Quality, at the Right Time, in the Right Quantity, and at the Right Price, ensuring excellence and value every time.

100% Parts

Traceability

We ensure 100% traceability from raw material to finished product, guaranteeing quality, compliance, and swift defect resolution throughout the production process.

Real Time

Monitoring

Uses real-time monitoring to track each production stage. This boosts precision, reduces downtime, and upholds quality standards. Our system ensures transparency and control throughout manufacturing.

Quality Control Process & Methods

Our quality control process is comprehensive and meticulously designed to ensure that every product we manufacture meets the highest standards of quality and reliability.

Incoming Material

Inspection

We conduct thorough inspections of all incoming raw materials to ensure they meet our stringent quality criteria before they enter our production process.

In-Process

Quality Checks

Our skilled quality control team performs regular inspections at various stages of the manufacturing process. This includes first article inspections, in-process inspections, and random sampling to detect and correct any deviations early on.

Real Time Data Collection & Monitoring

We leverage real-time data collection to enhance quality control by monitoring each stage of production. This method ensures immediate issue detection and consistent adherence to quality standards.

Final Product

Inspection

Before any product is shipped to our customers, it undergoes a final inspection to verify its conformity to specifications and quality standards. This includes dimensional checks, visual inspections, and functional testing.

Statistical Process

Control

We utilize SPC techniques to monitor and control our manufacturing processes. This helps us identify trends and variations, allowing us to implement corrective actions promptly and maintain consistent quality.

Corrective and

Preventive Actions

We have a robust CAPA system in place to address any quality issues that arise. This involves identifying the root cause, implementing corrective measures, and preventing recurrence.

ISO 9001 : 2015 Certified

MicroTech Pressings, an ISO 9001 : 2015 certified leader progressing towards Six Sigma and aiming for 0PPM, is committed to delivering zero-defect sheet metal parts to automotive OEMs. Our pursuit of IATF 16949 compliance underscores our dedication to quality, ensuring we meet the highest industry standards. By prioritizing precision, we guarantee our partners achieve their quality objectives, enhancing product performance and customer satisfaction.

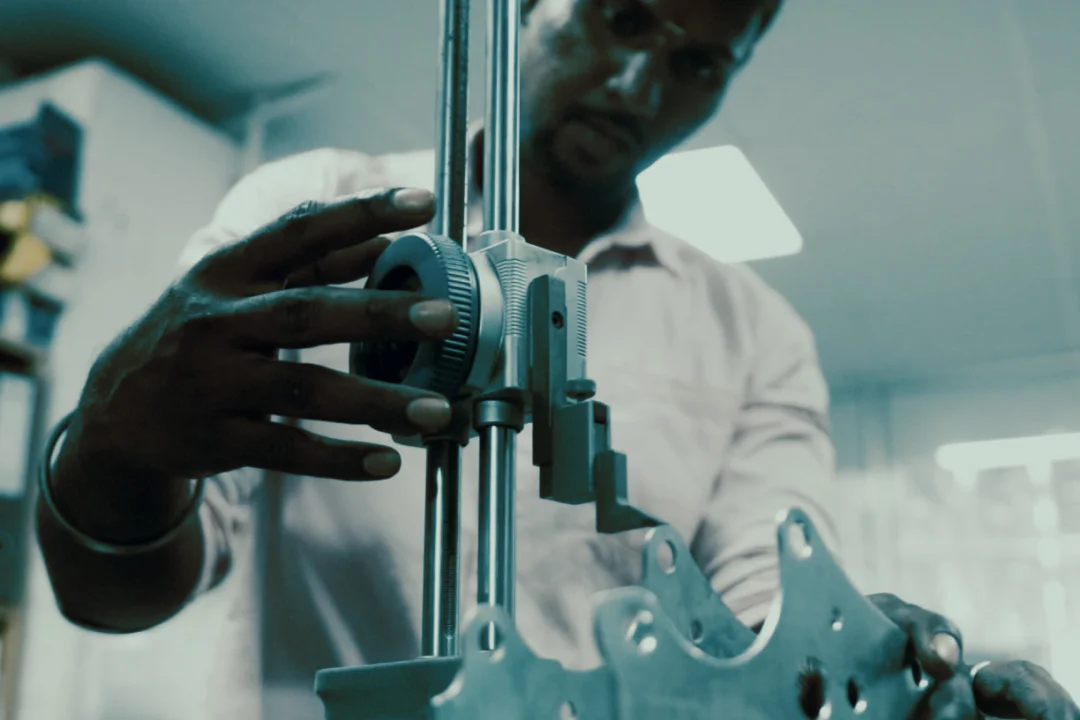

Quality Control (Equipment / Instruments)

Microtech Pressing is equipped with advanced quality control instruments and equipment to ensure the highest level of precision and accuracy in our products.

Our quality control team is trained to use these advanced instruments and follow strict procedures to ensure the integrity and reliability of our products. By leveraging the latest technology and adhering to rigorous quality control methods, we guarantee that every product leaving our facility is of the highest quality.

At Microtech Pressing Private Limited, quality control is not just a process – it is a commitment to excellence that permeates every aspect of our operations. Our advanced equipment, meticulous methods, and dedicated team ensure that we consistently deliver products that meet and exceed our customers’ expectations.

Equipment

Instruments

Our quality control team expertly utilizes advanced instruments and follows strict protocols to uphold product integrity. By integrating the latest technology with meticulous methods, we ensure every product meets our high standards of excellence.