Microtech Pressings specializes in sheet metal welding and sub-assemblies, enabling the production of complex products with precision and zero defects. Our capabilities ensure that we meet the specific requirements of diverse industries, delivering high-quality results every time.

Sectors We Serve & Aim to Serve

At Microtech Pressings, we specialize in providing high-quality sheet metal components manufacturing, including precision welding sub-assemblies and custom tooling and dies. Our expertise extends to complete reverse engineering and the production of sheet metal parts tailored for the automotive, home appliances, and industrial sectors, ensuring reliable and efficient solutions for your manufacturing needs.

Commercial Vehicles

Automotive

Passenger

Vehicles

Automotive

Home

Appliances

White Goods

Civil Aviation

and Defense

Aerospace

MCBs &

IT hardware

Electricals & Electronics

Medical

Equipement

Healthcare

Our Core Services

Microtech Pressings excels in sheet metal forming, delivering precise and durable components tailored to the unique needs of the automotive, home appliance, and industrial sectors. Our advanced techniques and commitment to quality ensure that we consistently meet and exceed industry standards, providing reliable solutions for all your sheet metal forming requirements.

Sheet Metal Press Components Manufacturing

Microtech Pressings is dedicated to precision sheet metal component manufacturing, helping clients across various sectors achieve their goals in quality, cost efficiency, timely delivery, and overall performance. Our expertise and commitment to excellence ensure that we deliver high-quality solutions that meet your strategic objectives.

Sheet Metal Welding Sub - Assemblies

Achievement

Our proficiency in metal forming has been acknowledged through various achievements and recognitions:

Client Satisfaction

We have successfully delivered high-precision components to numerous clients across diverse industries, earning their trust and fostering long-term partnerships. Our dedication to quality and reliability has positioned us as a preferred supplier for many leading companies.

Innovative Solutions

Our commitment to innovation has led to the development of unique forming solutions that address complex client specifications and industry challenges. We take pride in our ability to tackle demanding projects and deliver results that surpass client expectations.

Quality Certifications

Our metal forming processes are certified to ISO 9001:2015 standards, reflecting our dedication to maintaining the highest levels of quality in all our products and services. This certification underscores our commitment to continuous improvement and customer satisfaction.

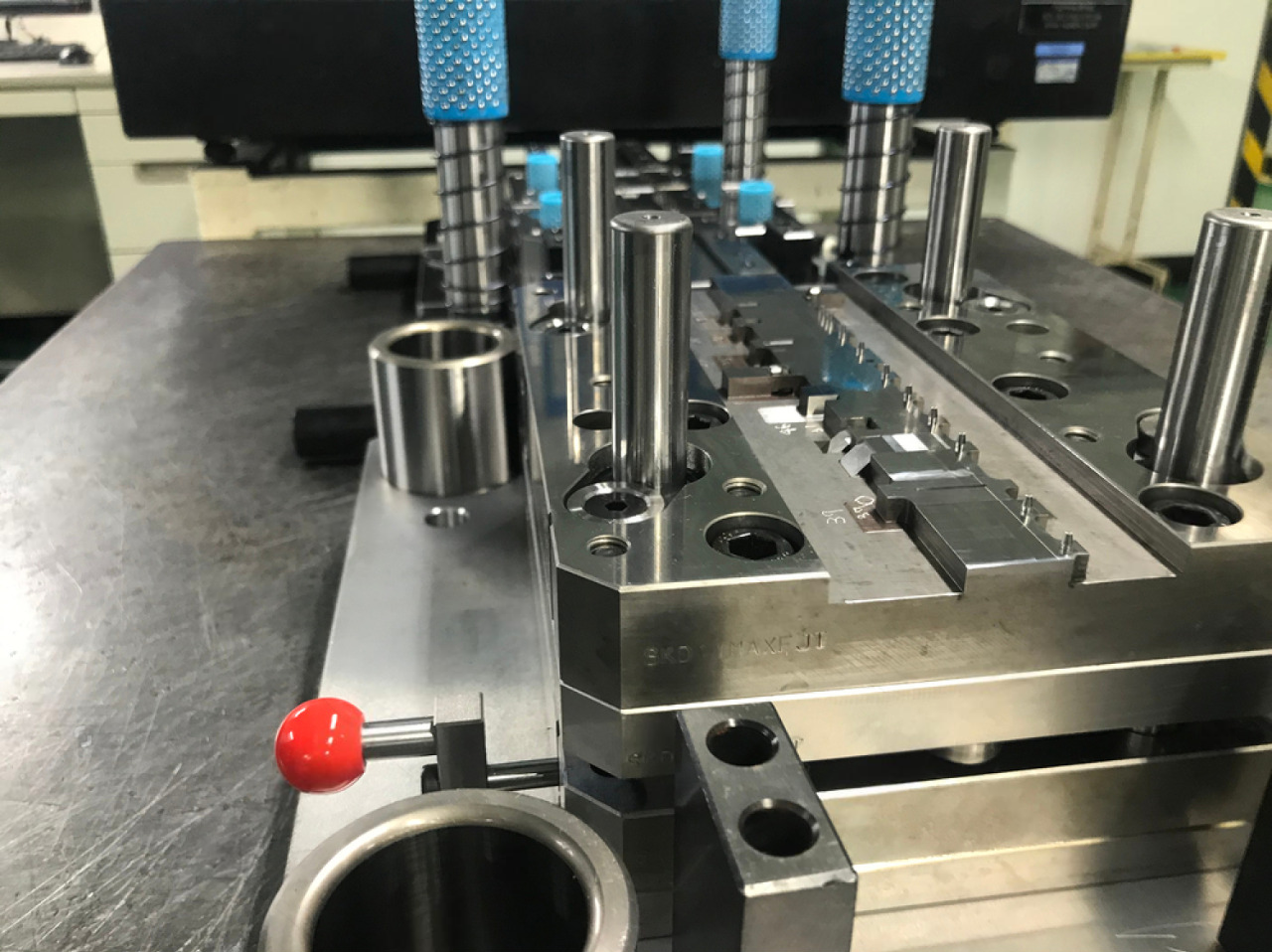

Tooling & Dies

Tools and dies are critical in achieving precision and quality in sheet metal components manufacturing. At Microtech Pressings, our extensive expertise ensures that we deliver top-notch tooling solutions, precisely tailored to meet the stringent demands of the industries we serve.

Tools & Die Design for Sheet Metal Components

Microtech Pressings excels in designing tools and dies for sheet metal components manufacturing, enabling the production of complex products with exceptional precision. Our talented team of die and tool design engineers, coupled with advanced software tools, ensures optimal designs that minimize raw material wastage. This approach not only enhances efficiency but also supports sustainable manufacturing practices across various industries.

Sheet Metal Components Tools & Die Manufacturing and MRO

Microtech Pressings specializes in manufacturing tools and dies for sheet metal components and MRO, crucial for producing complex products with precision. Our team of skilled die and tool design engineers, equipped with cutting-edge technology, ensures exceptional accuracy and efficiency. This expertise enables us to meet the most demanding requirements and deliver high-quality solutions.

Reverse Engineering and Manufacturing of Sheet Metal Components

Microtech Pressings excels in reverse engineering and manufacturing sheet metal components, transforming existing designs into precise, high-quality products. Our expertise ensures accurate replication and enhancement, meeting the exacting standards of various industries.

Complete Reverse Engineering from Components to Die

MicroTech Pressings specializes in complete reverse engineering, transforming components into high-precision dies with unmatched expertise. Using advanced design tools and skilled craftsmanship, we analyze existing parts to recreate accurate die designs tailored to exact specifications. Our capabilities include detailed 3D modeling, material selection, and precision machining for flawless die production. This comprehensive approach ensures seamless replication and high-quality outcomes, supporting industries with reliable, cost-effective solutions.

Notable Achievement

Our expertise in dies and tool manufacturing has led to several significant achievements:

Industry Awards

We have received multiple awards recognizing our innovative tooling solutions and precision manufacturing capabilities. These accolades highlight our commitment to excellence and our position as a leader in the industry.

Client Success Stories

Our custom-designed tools have enabled clients to achieve remarkable improvements in their manufacturing processes. By providing high-quality tools that enhance efficiency and reduce costs, we have helped our clients gain a competitive edge in their respective markets.

Technological Advancements

We continuously invest in the latest tooling technologies and methodologies, ensuring that we remain at the cutting edge of the industry. Our dedication to technological advancement enables us to deliver tools and dies that meet the most demanding specifications and contribute to the success of our clients.