to ensure the availability and maintenance of critical components.

CHECK AREA

through rigorous testing and inspection, guaranteeing

the highest standards.

ready to meet global standards and exceed

customer expectations.

Shop Floor

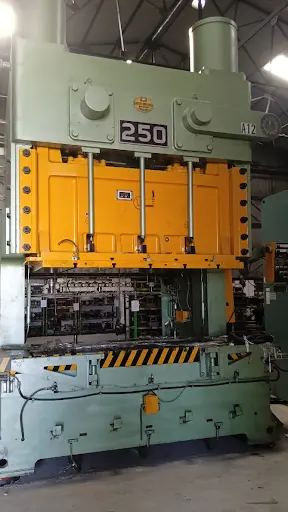

Our shop floor has expanded with the new 8000 sq.ft. facility in Sriperumbudur, Chennai. This spacious area accommodates our extensive range of specialized machinery, including transfer presses, hydraulic presses, and servo presses. We’re planning to further enhance our capabilities by adding 100, 200, and 250-ton capacity power presses in FY24-25, reinforcing our ability to produce high-quality sheet metal automotive parts with precision.

Core Machines / Equipment

Microtech Pressings’ core machines include high-tonnage power presses, progressive die stamping machines, and, soon, expanded capacity with new presses ranging from 100 to 250 tons in FY24-25. These machines form the backbone of our production process, ensuring we meet the highest standards of precision and consistency.

Amada – 110Ton Power Press Machine

Bansal – 80Ton Power Press Machine

Bansal – 110Ton Power Press Machine

Bansal – 160Ton Power Press Machine

Yangli – 200Ton Power Press

Aida – 150Ton Power Press Machine

Wasino – 200Ton Power Press

Amada – 250Ton Power Press Machine

Secondary Machines / Equipment

Our facility is equipped with secondary machines that complement our core operations, including precision tool room machines and supplementary equipment. In FY24-25, we plan to enhance our quality assurance capabilities by adding a Hardness Testing Machine, further ensuring that every component meets stringent industry standards.

MSW Coil Feeder T-5mm W-600mm 2.5Ton

Boli – Coil Feeder T-3.2mm W-600mm 1.8Ton

Machines for Welding Sub-assemblies

Our MIC and ARC welding machines support a wide range of welding sub-assemblies, ensuring robust and precise welding operations. These machines are housed in our expanded Sriperumbudur facility, contributing to the overall structural integrity and durability of our finished products.

Rilon – Arc Welding Machine

Migatronic Mig Welding 400A

Tooling & Die

Over 17 years experience & knowledge of international industrial systems, dedicated to provide the best economical solutions to our valued customers.

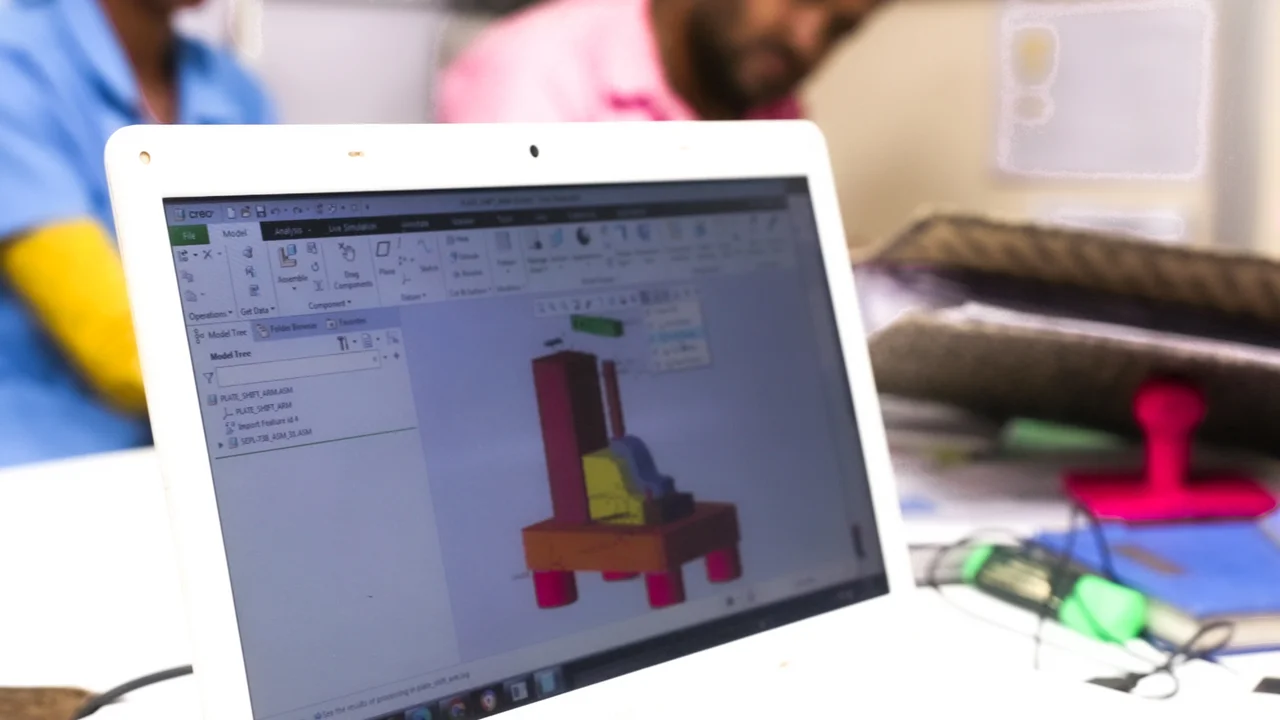

Design Centre

The Tooling & Die Design Centre at MicroTech Pressings, now supported by the new plant, continues to be the hub of innovation. We design and develop a variety of advanced tools and dies, including blanking, forming, and compound dies, essential for high-quality, defect-free automotive parts production.

Dies Maintenance and Repair

The Tooling & Die MRO section is dedicated to the maintenance, repair, and operational support of our tooling and dies. With our new plant in Sriperumbudur, we have enhanced our capacity to maintain these critical tools, ensuring seamless and efficient production processes.

Tool Room Facilities

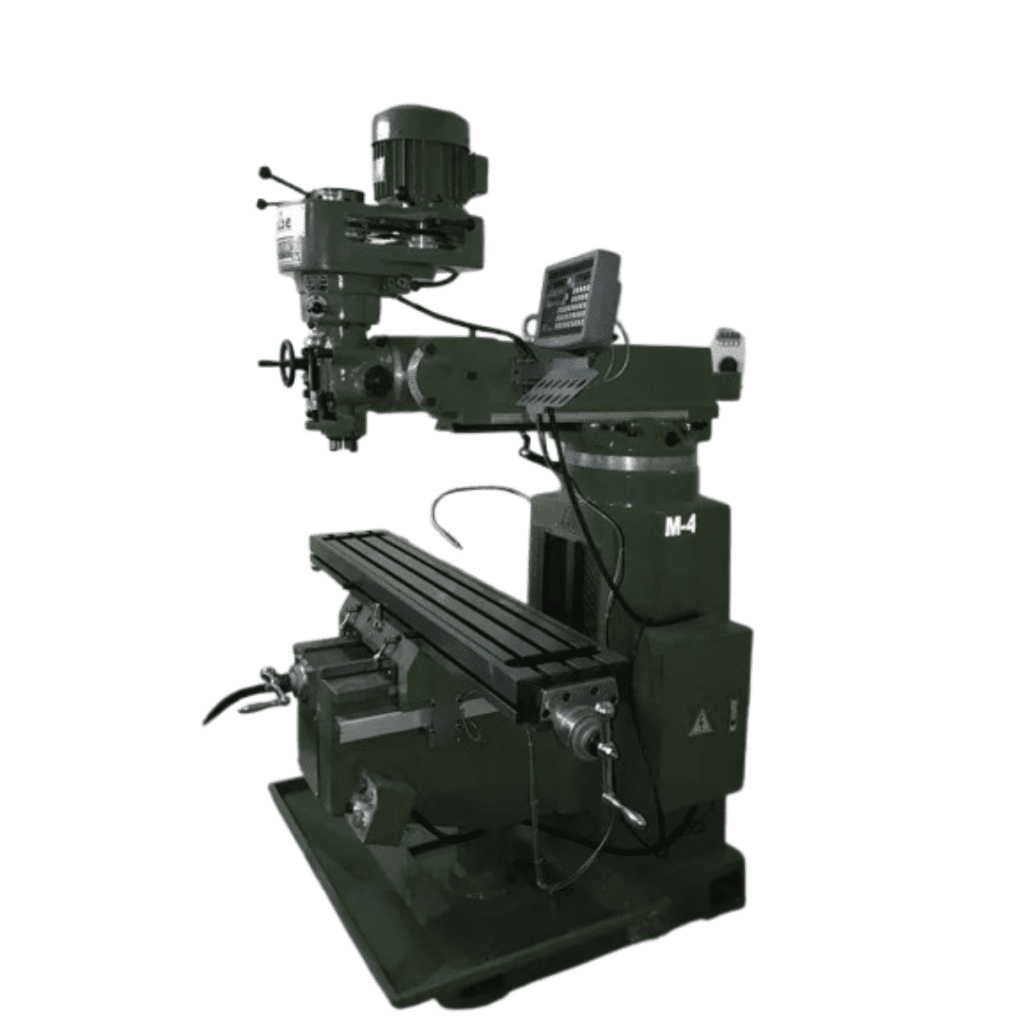

Our Tool Room is equipped with state-of-the-art machinery and now benefits from the additional space and resources provided by the Sriperumbudur facility. This enables us to create and maintain the precision tools required for high-quality automotive parts production with even greater efficiency.

Tool Room Machines / Equipment

MicroTech Pressings’ tool room is equipped with advanced machines for precise tooling and component manufacturing. Key facilities include a Plano Milling Machine, Hydraulic Surface Grinding Machine, and M1TR for versatile operations. Additional capabilities include radial and vertical drilling, and surface grinding to ensure top-notch accuracy and quality

GAMT – Surface Grinding Machine

Shubam – Vertical Drilling Machine

MCPRO-CH Radial Drilling Machine

MCPRO-CH M1TR Milling Machine

Prayosha – Hydraulic Surface Grinding Machine

Hercules – Plano Milling Machine

Quality Room Facilities

Quality assurance is paramount at MicroTech Pressings. Our Final Inspection Area of 2500 sq. ft. in the new plant is equipped with advanced testing and inspection equipment. Plans to add a Hardness Testing Machine in FY24-25 will further enhance our ability to meet and exceed quality standards.

IT – Hardware & Software

Our IT infrastructure includes cutting-edge hardware and software systems that support every aspect of our operations, from production management to quality control. The new Sriperumbudur plant is fully integrated with these systems, ensuring seamless operational efficiency across all processes.

ERP and CRM Integration

We utilize ERP software like Tally and CRM tools to streamline financial operations, manage customer relationships, and enhance overall efficiency.

Networking and Industry 4.0

Our secure LAN supports internal communications, while Industry 4.0 tools optimize our manufacturing processes for greater efficiency and responsiveness.

Material Management

Efficiently managing material flow to ensure seamless production and quality output at Microtech Pressings.

Raw Material Storage

Material Management features 2500 sq.ft. for raw material storage, ensuring steady supply and uninterrupted manufacturing.

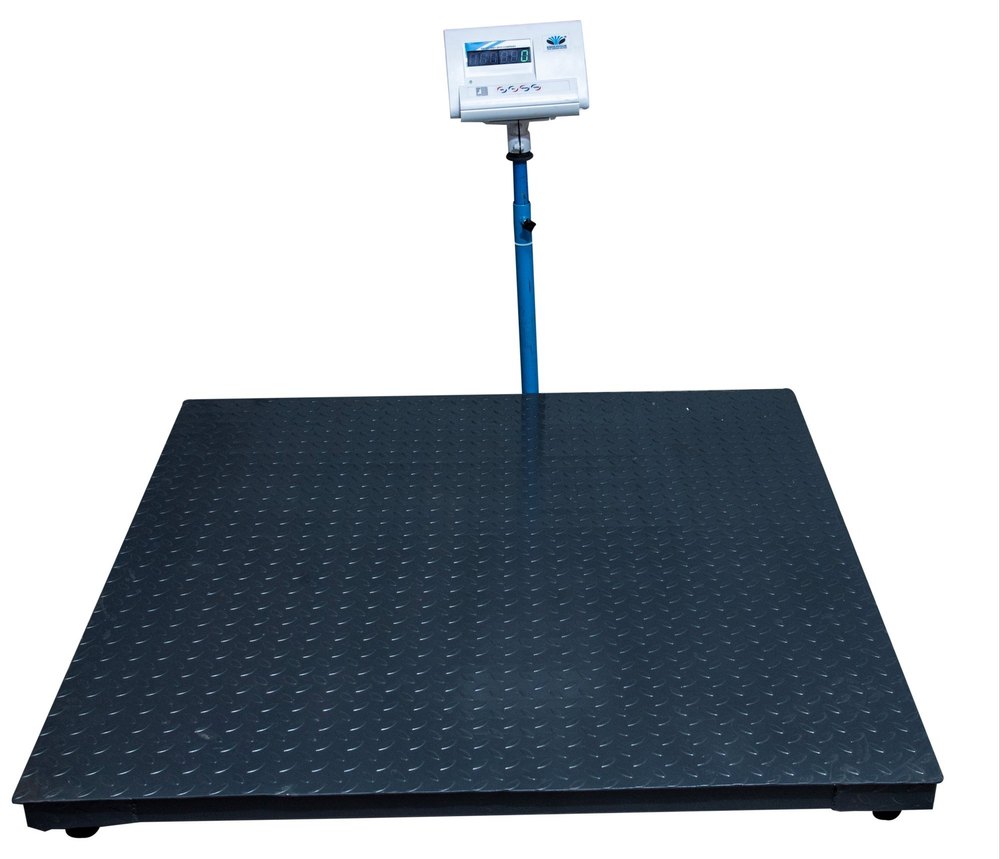

Material Handling Machines / Equipment

Material Handling includes manual and electronic forklifts, with a 2500 sq.ft. loading/unloading area in the new plant.

Other Facilities

In addition to our core production facilities, Our Plant is equipped with essential areas designed to optimize our operations. The Finished Goods Area spans 2,500 sq. ft., providing ample space for ready-to-dispatch products. A 3,000 sq. ft. Open Bay Area is dedicated to the efficient movement of goods, ensuring smooth logistics. To maintain operational efficiency and meet client demands, the plant is powered by a 220HP generator, guaranteeing continuous, non-stop production.

ACE – Battery Operated Forklift

Shastha – Manual Forklift 1Ton

PKD – Electronic Weight machine 5Ton

GMS – Electronic Weight Machine 300kg

Rilon – Arc Welding Machine

Migatronic Mig Welding 400A