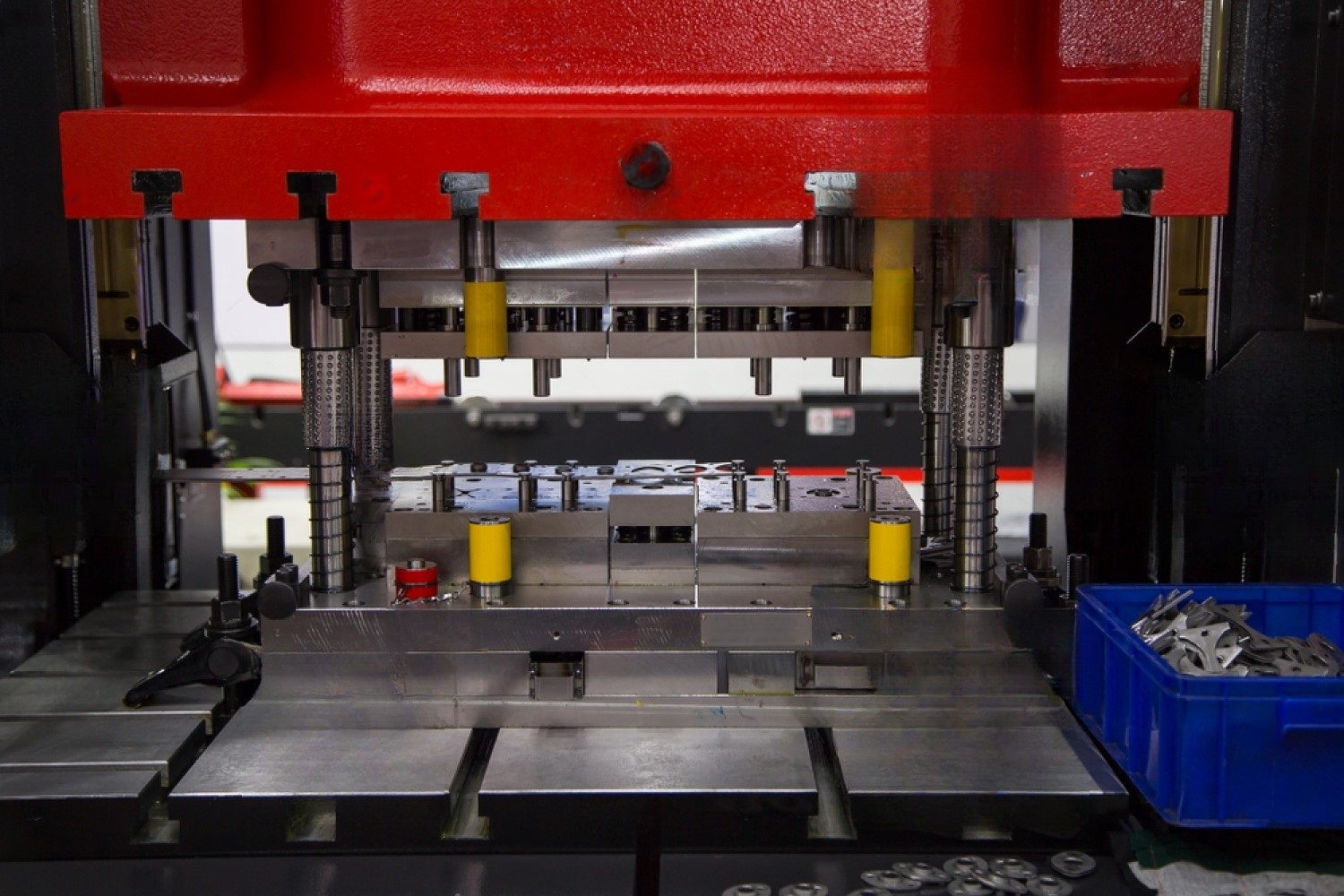

Capacity expansion achieved with addition of more power presses.

We Drive Excellence & Inspire Innovation

Founded in 2007, MicroTech Pressings has been your trusted partner in precision sheet metal components manufacturing for over 17 years. We are proud to be a leading manufacturer, specializing in high-quality sheet metal parts and components that cater to the automotive, white goods, and engineering sectors.

At MicroTech Pressings, we have honed our expertise in precision sheet metal stamping, deep-drawn components, welded sheet metal sub-assemblies, design and manufacturing of dies and tools. Our dedication to excellence and innovation ensures that every product we create meets the rigorous standards of our diverse clientele.

Our commitment to quality is further validated by our ISO 9001 : 2015 certification, which underscores our ability to consistently deliver products that meet and exceed industry standards. We understand the importance of reliability and efficiency in manufacturing, and we pride ourselves on delivering solutions that are on time, within budget, and precisely tailored to your specifications.

Over the years, we have built a reputation for excellence, driven by a passion for precision and a commitment to customer satisfaction. Our state-of-the-art manufacturing facilities, combined with our skilled workforce, enable us to tackle complex projects and deliver superior results. Whether you need custom components for a new product line or high-volume production runs, MicroTech Pressings is equipped to meet your needs with the highest quality standards.

Join us on our journey of innovation and excellence as we continue to serve the evolving needs of the automotive, white goods and engineering industries. At MicroTech Pressings, your success is our mission.

Vision

Our vision is to be a renowned sheet metal components manufacturer, delivering customer delight by consistently exceeding expectations through precision, quality, innovation, and employee empowerment.

Mission

Deliver zero-defect, precision-engineered sheet metal components of the highest quality to automotive, home appliances, aerospace, healthcare, electrical and electronics industries.

Our Motto

Drive innovation and employee empowerment, delivering products on time, at optimal cost, with zero defects and seamless customer service.

Our Journey - 17+ Years & Counting

MicroTech Pressings Started its operations in Ambattur Chennai, Tamil Nadu, India.

Shop floor expansion and Capacity is augmented with addition of advanced power presses and coil feeders.

Commissioned New Factory in Sriperumbudur, Chennai, India; 13,000 sq.ft. added exclusively for shop floor.

More power presses upto 250ton, coil feeders, material handling and quality control equipment added.

Infrastructure

MicroTech Pressings is significantly upgrading its infrastructure, boasting a spacious shop floor complemented by a dependable power generator for seamless production. Our facility is meticulously organized into specialized zones for raw material storage, sub-assembly welding, final inspection, finished goods storage, and loading/unloading, alongside an open bay for effortless transport logistics. Anticipated enhancements include the introduction of 250-ton power presses, sophisticated finishing, quality testing, and material handling equipment. Emphasizing our commitment to unparalleled quality, we’re advancing our capabilities with sub-assembly and state-of-the-art robotic welding processes. This evolution is further supported by our leap towards full digitalization, employing ERP systems and Industry 4.0 technologies to elevate transparency, offering real-time visualization, and refining process control for optimal efficiency and quality.

MicroTech Pressings’ superior quality stems from our exclusive raw material storage and advanced inventory management, ensuring lot-wise traceability. This meticulous approach guarantees the integrity of materials and finished products, allowing us to swiftly identify and address any quality issues. Our commitment to transparency and precision in tracing components from source to dispatch assures customers of consistent, high-quality sheet metal parts, reinforcing our role as a trusted partner in the automotive industry.

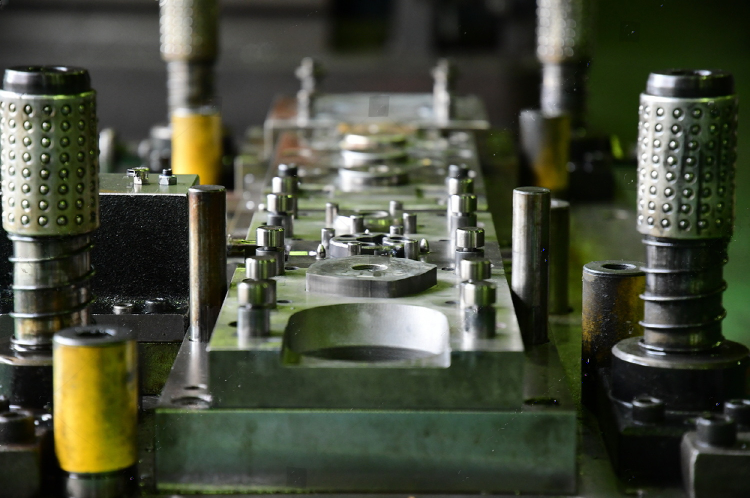

MicroTech Pressings’ shop floor is outfitted with an impressive line-up of specialized machinery to ensure the highest quality in sheet metal automotive parts. Our arsenal includes transfer presses, hydraulic presses, servo presses, punch presses, turret punch presses, and progressive die stamping machines, ranging from 50 to 250 tons. This diverse range of equipment enhances our flexibility and capability, allowing us to produce a wide variety of superior sheet metal components for the automotive industry, meeting exacting standards with unparalleled precision.

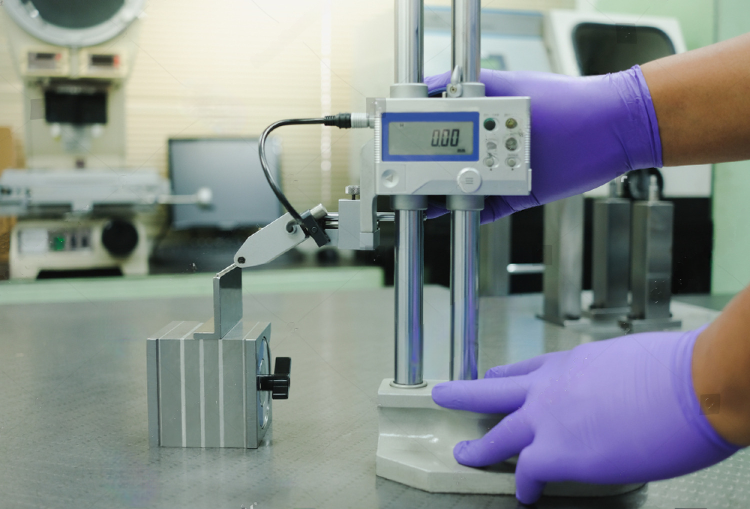

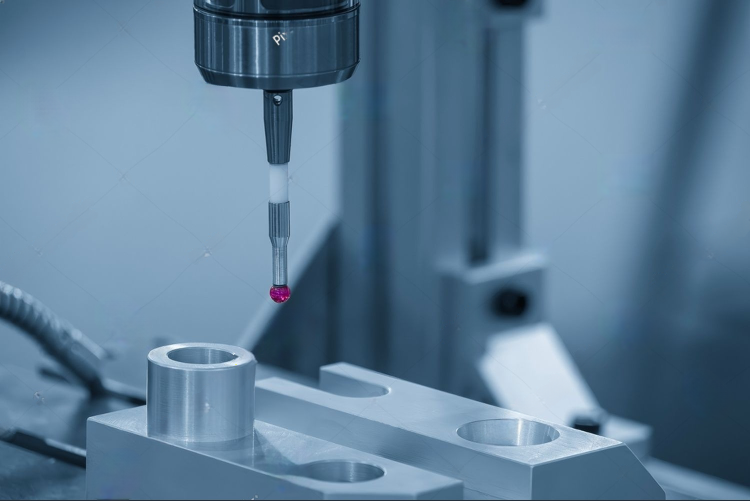

MicroTech Pressings employs a mix of standard and modern quality processes, including visual inspection, dimensional measurement, hardness testing, at times CMM, 3D scanning, and optical systems (by engaging 3rd party service providers), to ensure top-quality automotive parts. This comprehensive approach combines traditional and advanced techniques, enabling precise defect detection and dimensional accuracy. Our commitment to integrating cutting-edge inspection technologies supports our customers’ goals for zero defects and high-quality products, making us a trusted partner in automotive manufacturing.

MicroTech Pressings employs a mix of standard and modern quality processes, including visual inspection, dimensional measurement, hardness testing, at times CMM, 3D scanning, and optical systems (by engaging 3rd party service providers), to ensure top-quality automotive parts. This comprehensive approach combines traditional and advanced techniques, enabling precise defect detection and dimensional accuracy. Our commitment to integrating cutting-edge inspection technologies supports our customers’ goals for zero defects and high-quality products, making us a trusted partner in automotive manufacturing.

Core Work Areas

At Microtech Pressings, we specialize in providing high-quality sheet metal components manufacturing, including precision welding sub-assemblies and custom tooling and dies.

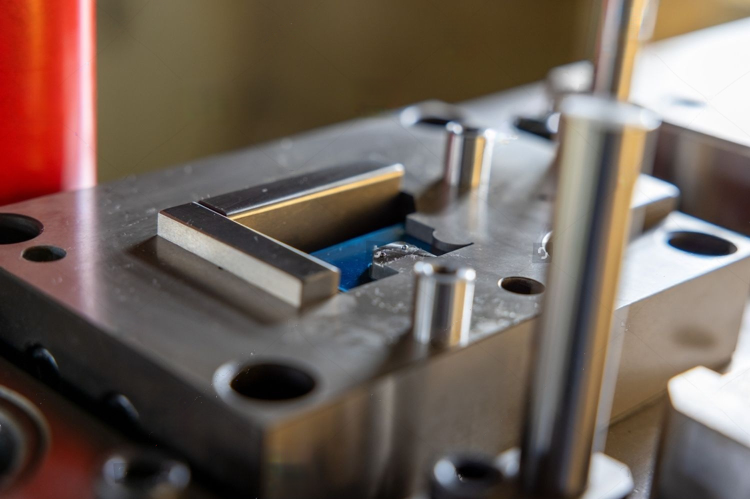

Sheet Metal Pressed Components Manufacturing

We are experts in manufacturing defect-free sheet metal components with high precision and best quality at optimal cost.

Sheet Metal Components Welding Sub-Assemblies

Specializing in premium welded sub-assemblies, we deliver durable and reliable sheet metal solutions for all engineering applications.

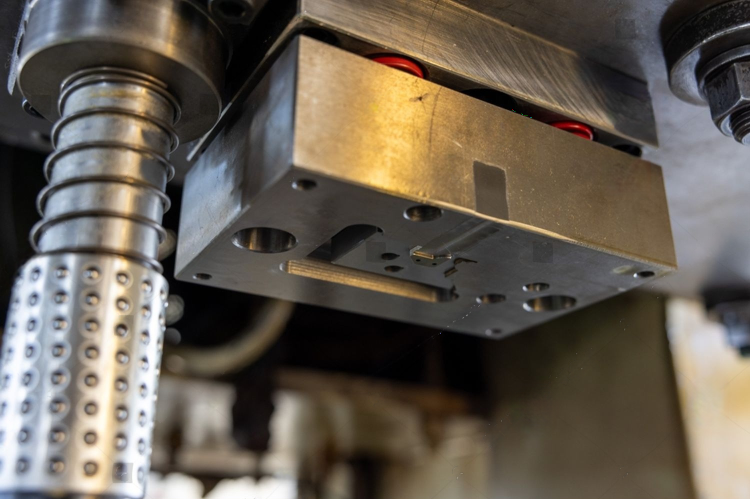

Design and Manufacturing of Dies and Tools for Sheet Metal Components

Our in-house die and tool manufacturing ensures customized, high-precision tooling solutions.

Team's Expertise

At Microtech Pressing Private Limited, our greatest asset is our team of highly skilled professionals. With decades of combined experience in the mechanical manufacturing industry, our team brings unparalleled expertise and dedication to every project.

Experienced Engineers

Our engineering team comprises experts in mechanical and manufacturing engineering who are adept at designing innovative solutions and optimizing production processes. Their technical acumen ensures that every product we develop meets the highest standards of precision and efficiency.

Skilled Technicians

Our technicians are proficient in operating advanced machinery and implementing cutting-edge manufacturing techniques. Their hands-on experience and attention to detail are crucial in maintaining the quality and consistency of our products.

Dedicated Quality Control Specialists

Our quality control team is committed to upholding the rigorous standards that define Microtech Pressing. With extensive knowledge in quality assurance practices, they ensure that every component we produce adheres to stringent quality criteria.

Customer Service Professionals

Our customer service team is dedicated to providing exceptional support to our clients. Their responsiveness and commitment to customer satisfaction are integral to building and maintaining long-term partnerships.

Our Capabilities

Advanced

Quality Control

MicroTech Pressings stands out in the automotive sector with its sophisticated quality control protocols. By integrating diverse quality inspection equipment and systems, we ensure that each component meets the stringent precision and reliability requirements of the automotive industry. This commitment to advanced inspection techniques underpins their capability to consistently achieve zero defects in their products.

Specialized

Tooling Expertise

At the heart of MicroTech Pressings’ operations is its extensive use of specialized tools and dies, such as progressive, transfer, and compound dies. This arsenal of precision tooling enables the company to tackle a broad spectrum of manufacturing challenges, producing high-quality, defect-free components that precisely meet the specifications of automotive clients. Our tooling expertise is a critical factor in their ability to deliver custom solutions and maintain high standards of quality.

Manufacturing

Flexibility & Innovation

MicroTech Pressings demonstrates exceptional flexibility and innovation in manufacturing, leveraging a variety of presses including transfer, hydraulic, servo, punch, and turret punch presses. This diverse machinery portfolio, coupled with a commitment to technological advancement and continuous process improvement, allows for the efficient production of a wide range of sheet metal parts. Such versatility is key to adapting to the evolving demands of the automotive industry, ensuring both quality and efficiency in production.

Awards & Recognition

ISO 9001 : 2015 Certified

MicroTech Pressings, an ISO 9001 : 2015 certified leader progressing towards Six Sigma and aiming for 0PPM, is committed to delivering zero-defect sheet metal parts to automotive OEMs. Our pursuit of IATF 16949 compliance underscores our dedication to quality, ensuring we meet the highest industry standards. By prioritizing precision, we guarantee our partners achieve their quality objectives, enhancing product performance and customer satisfaction.

Our Esteemed Clients

MicroTech Pressings is proud to serve a diverse array of clients across the automotive and metal manufacturing industries. Our commitment to quality, efficiency, and innovation has earned us the trust of leading companies. We value our partnerships and continuously strive to exceed our clients’ expectations with superior products and services. Join our growing list of satisfied customers and experience the MicroTech Pressings difference.

Testimonial